-33%

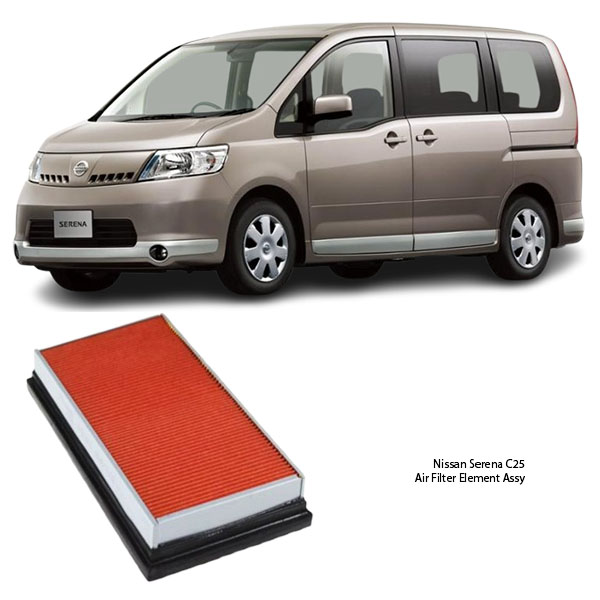

Get Nissan Serena C25 Air Element Element Assy 16546-V0100 in Kenya

The Air Element Assembly, also known as the Air Filter Element Assembly, is a crucial component of a vehicle’s intake system. It plays a fundamental role in filtering dust, dirt, and debris from the incoming air before it enters the engine’s combustion chamber. Ensuring a clean air supply is vital for optimal combustion, engine performance, and fuel efficiency.

In this comprehensive guide, we will explore:

- What is an Air Element Assembly?

- Types of Air Filter Elements

- Functions of an Air Element Assembly

- Benefits of a Clean Air Filter Element

- Common Symptoms of a Dirty or Failing Air Element

- Causes of Air Element Contamination

- Inspection and Maintenance Tips

- How to Replace an Air Element Assembly

- Choosing the Right Air Filter for Your Vehicle

What is an Air Element Assembly?

The Air Element Assembly consists of an air filter element, which is the core filtration component, housed within an air box or intake system. It prevents harmful contaminants from reaching the engine, ensuring only clean, oxygen-rich air is used for combustion.

Main Components of an Air Element Assembly:

✔ Filter Media (Paper, Foam, or Cotton) – Traps dust, dirt, and particles.

✔ Air Box or Housing – Secures the filter in place and prevents air leaks.

✔ Intake Ducts – Direct airflow from the outside environment to the engine.

✔ Seals & Gaskets – Ensure proper sealing to prevent unfiltered air from bypassing the filter.

Types of Air Filter Elements

1. Paper Air Filter Elements

🔹 Made of pleated paper material for effective filtration.

🔹 Common in passenger vehicles and light trucks.

🔹 Disposable and requires regular replacement.

2. Foam Air Filter Elements

🔹 Used in off-road vehicles, motorcycles, and racing applications.

🔹 Requires oiling for enhanced filtration efficiency.

🔹 Offers better reusability but needs frequent maintenance.

3. Cotton Air Filter Elements

🔹 Reusable and washable.

🔹 Commonly found in performance or aftermarket air filters.

🔹 Provides better airflow and longer service life.

4. Carbon-Activated Air Filter Elements

🔹 Designed to absorb odors and harmful gases.

🔹 Found in modern vehicles with advanced intake systems.

🔹 Reduces the entry of harmful pollutants into the cabin.

Functions of an Air Element Assembly

✔ Filters Incoming Air

- Traps dirt, pollen, dust, and contaminants before they enter the engine.

✔ Ensures Optimal Air-Fuel Mixture

- Supplies clean air to maintain the correct air-to-fuel ratio, which is critical for efficient combustion.

✔ Protects Internal Engine Components

- Prevents dirt and particles from damaging cylinders, pistons, and valves.

✔ Enhances Fuel Efficiency

- Reduces engine strain, improving mileage and fuel economy.

✔ Improves Engine Power & Acceleration

- Allows consistent airflow, ensuring better throttle response.

✔ Minimizes Emissions

- Ensures proper combustion, reducing the production of carbon deposits and harmful gases.

Benefits of a Clean Air Filter Element

✔ Extends Engine Life – Prevents contaminants from damaging sensitive engine components.

✔ Optimizes Fuel Economy – A clean air element ensures the ideal air-fuel ratio, reducing fuel wastage.

✔ Increases Horsepower – Maintains unrestricted airflow, improving engine efficiency.

✔ Enhances Throttle Response – Ensures smooth acceleration and engine performance.

✔ Reduces Harmful Emissions – Helps maintain an efficient combustion process.

Common Symptoms of a Dirty or Failing Air Element

🚨 Reduced Acceleration and Power

- A clogged filter restricts airflow, leading to poor engine performance.

🚨 Increased Fuel Consumption

- A dirty filter disrupts the air-fuel mixture, causing the engine to work harder.

🚨 Check Engine Light (CEL) Activation

- Restricted airflow can cause sensor malfunctions, triggering the CEL.

🚨 Dark or Black Exhaust Smoke

- An improper air-fuel mixture can lead to excess fuel burning, resulting in dark exhaust fumes.

🚨 Unusual Engine Noises

- A clogged filter may cause the engine to idle roughly or misfire.

🚨 Visible Dirt or Debris on the Filter

- A heavily contaminated filter appears dirty and clogged, requiring replacement.

Causes of Air Element Contamination

🔧 Driving in Dusty or Polluted Areas – Increased exposure to airborne contaminants.

🔧 Extended Service Intervals – Failing to replace the air filter on time.

🔧 Poor Quality Fuel – Low-quality fuel can produce carbon deposits, clogging the filter.

🔧 Oil or Fuel Vapors – Some engines allow oil vapors to pass through the intake, contaminating the filter.

Inspection and Maintenance Tips

✔ Check the Air Filter Every 10,000-15,000 km – Replace or clean based on manufacturer recommendations.

✔ Inspect for Tears or Damage – A damaged filter allows unfiltered air to enter the engine.

✔ Shake Off Loose Dirt (If Applicable) – If the filter is not too dirty, gently remove debris.

✔ Use Compressed Air (For Reusable Filters) – Blow air from the clean side outward to remove contaminants.

✔ Replace with OEM-Recommended Filters – Avoid using cheap or low-quality air filters.

How to Replace an Air Element Assembly

🛠 Tools Required:

✔ Screwdriver

✔ Pliers (if necessary)

✔ Replacement Air Filter

🛠 Step-by-Step Replacement:

1️⃣ Locate the Air Filter Housing

- Typically found in the engine bay, secured by clamps or screws.

2️⃣ Remove the Air Box Cover

- Use a screwdriver or release clips to access the filter.

3️⃣ Take Out the Old Filter

- Inspect for dirt buildup, damage, or tears.

4️⃣ Clean the Housing (If Needed)

- Wipe away dust and debris before installing the new filter.

5️⃣ Insert the New Air Filter

- Ensure it fits snugly and seals properly in the housing.

6️⃣ Secure the Housing Cover

- Reattach clips or screws and check for any gaps.

7️⃣ Start the Engine and Test

- Listen for smooth operation and check for any air leaks.

Choosing the Right Air Filter for Your Vehicle

✔ OEM vs. Aftermarket:

- OEM filters provide the best fit and performance, while aftermarket options vary in quality.

✔ Filter Material:

- Cotton and foam filters are reusable, while paper filters require replacement.

✔ Vehicle Compatibility:

- Ensure the filter matches your car’s make, model, and engine specifications.

✔ Environmental Considerations:

- Reusable air filters (e.g., K&N filters) are eco-friendly but require periodic cleaning and oiling.

✔ Brand Reputation & Warranty:

- Choose brands known for high-quality filtration and durability.

Final Thoughts

The Air Element Assembly is a key component in engine protection and performance. Regular inspection, cleaning, and replacement are essential to maintain fuel efficiency, engine longevity, and reduced emissions. Investing in a high-quality air filter element enhances long-term engine protection, making it a crucial part of routine vehicle maintenance.

Follow us on Facebook for more parts.