-18%

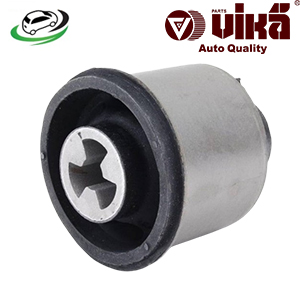

Get Rear Axle Trailing Arm Bushing Audi TT 2000-2006/Beetle 1998-2010/Golf 1999-2006/Jetta 1999-2005 1J0501541C

The trailing arm bushing is a critical component of a vehicle’s suspension system, particularly in systems that use trailing arms to control wheel motion. This component provides the necessary pivot point between the trailing arm and the vehicle’s frame or body, ensuring smooth and stable operation. Here’s a detailed examination of the construction, function, benefits, common issues, signs of failure, and maintenance of trailing arm bushings.

Construction and Function of a Trailing Arm Bushing

Construction:

- Materials:

- Rubber: Most trailing arm bushings are made from rubber, which offers flexibility and vibration damping.

- Polyurethane: Some performance or aftermarket bushings use polyurethane for enhanced durability and performance characteristics.

- Metal Sleeve: Typically, there’s a metal sleeve in the center of the bushing through which the mounting bolt passes, providing a secure attachment point.

- Design:

- Cylindrical Shape: The bushing is generally cylindrical, fitting snugly within the trailing arm’s mounting points.

- Bonded or Press-Fit: The rubber or polyurethane is bonded to the metal sleeve, or the entire bushing assembly is press-fit into the trailing arm.

Function:

- Pivot Point:

- Attachment: The bushing serves as the attachment point between the trailing arm and the vehicle’s frame or body.

- Motion Allowance: It allows for the necessary pivoting motion of the trailing arm as the suspension moves.

- Vibration Damping:

- Shock Absorption: The rubber or polyurethane material absorbs shocks and vibrations from the road, enhancing ride comfort.

- Noise Reduction: It helps reduce noise transmission from the suspension to the vehicle’s cabin.

- Stability and Alignment:

- Maintaining Alignment: The bushing helps maintain proper wheel alignment by providing a stable connection between the trailing arm and the vehicle.

- Reducing Deflection: It minimizes unwanted deflection of the trailing arm, ensuring consistent handling characteristics.

Benefits of Trailing Arm Bushings

- Enhanced Ride Comfort:

- Vibration Dampening: By absorbing road vibrations, the bushing contributes to a smoother and more comfortable ride.

- Noise Reduction: It reduces the transmission of road noise into the cabin, making for a quieter driving experience.

- Improved Handling:

- Stability: The bushing helps maintain the stability of the trailing arm, ensuring consistent handling and responsiveness.

- Alignment: Properly functioning bushings help maintain wheel alignment, crucial for predictable and safe handling.

- Durability:

- Long-Lasting Materials: High-quality bushings, especially those made from polyurethane, are designed to withstand the rigors of driving and last for many years.

- Protection: The bushing protects the trailing arm and mounting points from excessive wear and stress.

- Cost-Effective Maintenance:

- Affordable Replacement: Trailing arm bushings are relatively inexpensive and can be replaced without major disassembly.

- Preventative Maintenance: Regular inspection and timely replacement of worn bushings can prevent more significant suspension issues and costly repairs.

Common Issues with Trailing Arm Bushings

- Wear and Tear:

- Aging Rubber: Over time, rubber bushings can harden, crack, or deteriorate due to exposure to the elements and constant flexing.

- Polyurethane Degradation: While more durable, polyurethane bushings can also wear out under high-stress conditions.

- Noise:

- Squeaking or Creaking: Worn or damaged bushings can cause squeaking or creaking noises, especially when driving over bumps or rough roads.

- Clunking: Loose or excessively worn bushings can cause clunking noises as the trailing arm moves excessively.

- Reduced Performance:

- Increased Deflection: Worn bushings can allow more movement of the trailing arm, leading to increased deflection and reduced handling performance.

- Vibration Transmission: Deteriorated bushings can transmit more road vibrations to the chassis, reducing ride comfort.

- Misalignment:

- Suspension Misalignment: Worn or damaged bushings can cause misalignment of the trailing arm, affecting overall suspension geometry and performance.

- Tire Wear: Misalignment can lead to uneven or accelerated tire wear, reducing tire life and affecting handling.

Signs of Failing Trailing Arm Bushings

- Unusual Noises:

- Squeaking or Creaking: Persistent squeaking or creaking noises from the suspension, especially when going over bumps, can indicate worn bushings.

- Clunking Sounds: Clunking or knocking noises during acceleration, braking, or over rough roads can be a sign of excessive movement in the trailing arm due to worn bushings.

- Poor Handling:

- Increased Body Roll: If the vehicle exhibits more body roll during cornering, it could indicate that the trailing arm bushings are worn and not providing adequate support.

- Unstable Ride: A feeling of instability or looseness in the suspension, particularly when cornering, may suggest bushing issues.

- Visible Wear:

- Cracks or Splits: Visual inspection of the bushings may reveal cracks, splits, or signs of deterioration.

- Displacement: If the bushing appears displaced or is moving excessively within its mounting bracket, it’s likely worn or damaged.

- Tire Wear:

- Uneven Wear: Uneven tire wear, particularly on the rear tires, can be a sign of misalignment caused by worn bushings.

- Rapid Wear: Accelerated tire wear may also indicate suspension alignment issues related to bushing wear.

Maintenance and Replacement of Trailing Arm Bushings

- Regular Inspections:

- Visual Checks: Regularly inspect the trailing arm bushings for signs of wear, cracks, or displacement.

- Listen for Noises: Pay attention to any unusual noises from the suspension during driving, which may indicate worn bushings.

- Timely Replacement:

- Replace When Worn: Replace the bushings as soon as signs of wear or damage are detected to maintain vehicle stability and handling.

- Use Quality Parts: Opt for high-quality rubber or polyurethane bushings to ensure durability and performance.

- Professional Installation:

- Proper Fitment: Ensure that bushings are correctly fitted to avoid issues with alignment or excessive movement.

- Torque Specifications: Follow the manufacturer’s torque specifications when tightening the mounting bolts to avoid over-compression or under-tightening.

- Consider Upgrades:

- Polyurethane Bushings: For enhanced performance and durability, consider upgrading to polyurethane bushings.

- Performance Bushings: For high-performance or off-road vehicles, specialized bushings designed for specific driving conditions can be beneficial.

- Alignment Checks:

- Post-Installation Alignment: After replacing trailing arm bushings, it’s crucial to check and adjust the vehicle’s alignment to ensure proper suspension geometry and tire wear.

- Regular Alignment Maintenance: Regular alignment checks can help identify and correct issues caused by worn or damaged bushings.

Follow us on Facebook for more parts.