-33%

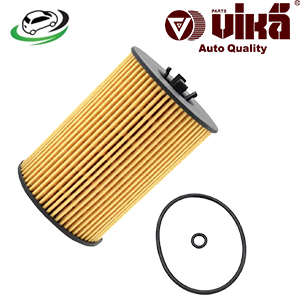

Get Oil Filter AUDI A3 8V FWD TDI / VW Beetle TDI/ Golf VII TDI/ Jetta VI TDI/ Passat B7 TDI 03N115562

The oil filter is a critical component in an internal combustion engine’s lubrication system. It plays an essential role in maintaining engine health by filtering out contaminants from the engine oil before it circulates through the engine. Clean engine oil is vital for lubricating moving parts, reducing friction, cooling the engine, and preventing wear and tear. The oil filter ensures that only clean oil reaches the engine components, thereby extending the life of the engine and improving its performance.

1. Design and Structure

Oil filters come in various designs, but they all serve the same purpose: to filter out harmful contaminants from the engine oil. The typical oil filter design includes the following key components:

- Filter Medium: The heart of the oil filter is the filter medium, a material designed to capture and hold contaminants while allowing clean oil to pass through. This medium is often made of cellulose, synthetic fibers, or a blend of both. Some high-performance filters use micro-glass fibers for superior filtration.

- Filter Housing: The filter medium is enclosed within a metal or plastic housing that protects it from damage and helps direct the flow of oil through the filter. The housing is designed to withstand the pressure and temperature of the engine environment.

- Base Plate: The base plate is a metal disc with perforations that allow oil to enter the filter. It is also where the filter attaches to the engine via a threaded hole in the center.

- Anti-Drainback Valve: Many oil filters include an anti-drainback valve, a rubber or silicone valve that prevents oil from draining out of the filter when the engine is turned off. This ensures that oil is immediately available to the engine upon startup.

- Bypass Valve: The bypass valve is a safety feature that allows oil to bypass the filter medium if it becomes clogged or if the oil is too thick (such as during a cold start). This ensures that oil continues to flow to the engine, even if it is not fully filtered.

- End Caps: End caps are located at the top and bottom of the filter medium, securing it within the housing and ensuring that oil flows correctly through the filter.

- Sealing Gasket: A rubber gasket forms a tight seal between the oil filter and the engine’s oil filter housing, preventing oil leaks.

2. Functionality

The oil filter’s primary function is to clean the engine oil by removing contaminants that can harm the engine. These contaminants include:

- Metal Particles: Tiny metal shavings can be produced as engine components wear against each other. If these particles are not filtered out, they can cause further abrasion and wear.

- Dirt and Dust: External contaminants like dirt and dust can enter the engine through the air intake and find their way into the oil. The filter prevents these particles from circulating through the engine.

- Carbon Deposits: Combustion byproducts can create carbon deposits in the oil. The filter helps remove these deposits, preventing sludge buildup.

- Oxidation Byproducts: Over time, engine oil can oxidize, leading to the formation of sludge and varnish. The oil filter helps capture these byproducts, keeping the oil clean.

How the Oil Filter Works:

- Oil Enters the Filter: As the engine runs, oil is pumped from the oil sump through the oil pump and into the oil filter. The oil enters the filter through the base plate.

- Filtration Process: The oil is forced through the filter medium, where contaminants are trapped. Clean oil passes through the medium and exits the filter.

- Oil Returns to the Engine: The filtered oil exits the oil filter and is directed back into the engine’s lubrication system, where it continues to lubricate, cool, and protect engine components.

- Bypass Valve Operation: If the filter medium becomes clogged or if the oil is too thick (for example, during a cold start), the bypass valve will open to allow unfiltered oil to flow directly to the engine. This prevents oil starvation but is only a temporary measure until the oil warms up or the filter is replaced.

3. Importance in Engine Operation

The oil filter is crucial for maintaining engine health and performance. Here’s why it’s so important:

- Protects Engine Components: By filtering out contaminants, the oil filter prevents abrasive particles from causing damage to critical engine components like the crankshaft, camshaft, bearings, and pistons.

- Maintains Oil Quality: The oil filter helps maintain the quality and viscosity of the engine oil by removing contaminants that can degrade the oil. This ensures that the oil remains effective in lubricating and cooling the engine.

- Prevents Sludge Buildup: Over time, unfiltered contaminants can lead to sludge buildup in the engine, which can block oil passages and reduce engine efficiency. The oil filter helps prevent sludge formation by removing contaminants from the oil.

- Extends Engine Life: Clean oil reduces wear and tear on engine components, extending the overall life of the engine. Regularly replacing the oil filter is a simple and cost-effective way to protect your engine.

4. Types of Oil Filters

There are several types of oil filters, each designed for specific applications and operating conditions:

- Full-Flow Oil Filters: Also known as primary oil filters, these are the most common type used in automotive engines. Full-flow filters are designed to filter all the oil that circulates through the engine, ensuring that it is clean and free of contaminants.

- Secondary Oil Filters: Also known as bypass filters, these work alongside the primary oil filter. They filter a smaller portion of the oil, removing finer particles that the primary filter might miss. Bypass filters are often used in heavy-duty or high-performance engines.

- Cartridge Oil Filters: These filters consist of a replaceable filter element housed within a reusable metal or plastic canister. Cartridge filters are becoming more popular due to their environmental benefits, as only the filter element needs to be replaced.

- Spin-On Oil Filters: Spin-on filters are a self-contained unit that includes both the filter medium and the housing. They are easy to replace, making them the most common type of oil filter used in vehicles today.

- Magnetic Oil Filters: These filters use magnets to attract and hold metal particles, preventing them from circulating through the engine. Magnetic filters are often used in conjunction with other types of filters for added protection.

- Centrifugal Oil Filters: These filters use centrifugal force to separate contaminants from the oil. The oil is spun at high speeds, causing heavier particles to be thrown to the outer edges, where they are trapped. Centrifugal filters are commonly used in industrial and heavy-duty applications.

5. Common Issues and Maintenance

While oil filters are generally reliable, they can encounter several issues if not properly maintained:

- Clogged Filter: Over time, the filter medium can become clogged with contaminants, reducing its efficiency and causing the bypass valve to open more frequently. A clogged filter should be replaced promptly to prevent engine damage.

- Oil Leaks: Improper installation or a damaged sealing gasket can cause oil leaks around the oil filter. Leaks can lead to low oil levels and reduced lubrication, potentially causing engine damage.

- Bypass Valve Failure: If the bypass valve fails to open when needed, it can cause oil starvation, leading to severe engine damage. Regular oil changes and filter inspections can help prevent this issue.

- Incorrect Filter Size: Using an incorrect oil filter can cause fitment issues, leading to leaks or poor filtration. Always use the filter recommended by the vehicle manufacturer.

Maintenance Tips:

- Regular Oil Changes: Regular oil changes are essential to maintaining the oil filter’s efficiency. Over time, the filter becomes saturated with contaminants, reducing its effectiveness. Changing the oil and filter at recommended intervals ensures that the engine receives clean oil.

- Inspect for Leaks: After installing a new oil filter, inspect the area around the filter for signs of oil leaks. Tighten the filter as necessary, but avoid over-tightening, which can damage the gasket.

- Use Quality Filters: Always use high-quality oil filters that meet or exceed the manufacturer’s specifications. Low-quality filters may not provide adequate filtration, leading to engine damage.

- Replace the Filter with Every Oil Change: It’s a good practice to replace the oil filter with every oil change, even if it appears to be in good condition. This ensures that the engine always has clean oil circulating through it.

6. Replacement and Installation

Replacing the oil filter is a straightforward process, but it’s important to do it correctly to avoid issues:

- Drain the Oil: Before replacing the oil filter, drain the engine oil by removing the drain plug from the oil pan. Allow the oil to drain completely into a suitable container.

- Remove the Old Filter: Use an oil filter wrench to remove the old oil filter. Turn the filter counterclockwise until it can be removed by hand. Be prepared for some oil to spill from the filter as you remove it.

- Inspect and Clean: Before installing the new filter, inspect the oil filter housing for any debris or old gasket material. Clean the area to ensure a proper seal.

- Install the New Filter: Apply a small amount of fresh engine oil to the gasket on the new oil filter. This helps create a better seal and makes it easier to remove the filter during the next oil change. Screw the new filter onto the housing by hand until it is snug, then give it an additional ¾ turn.

- Refill the Oil: After the new filter is installed, replace the drain plug and refill the engine with the recommended type and amount of oil. Start the engine and check for leaks around the oil filter.

Follow us on Facebook for more parts.