-6%

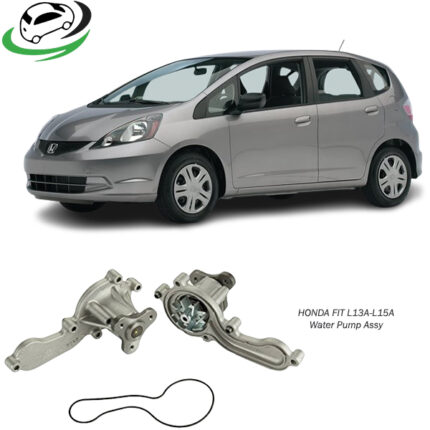

Get Honda Stream RN8 Engine Water Pump Assy H-63

The engine water pump assembly is a critical component of a vehicle’s cooling system. Its main purpose is to circulate coolant from the radiator to the engine and back, regulating the engine’s temperature and preventing it from overheating. Without a functioning water pump, an engine could overheat, leading to serious damage, expensive repairs, or even total engine failure. This detailed explanation covers the structure, functions, benefits, common issues, and maintenance of an engine water pump assembly.

1. Structure of an Engine Water Pump Assembly

The engine water pump assembly is a complex part that includes several smaller components that work together to ensure efficient coolant circulation. These components include:

- Pump Housing: The outer casing or shell that encloses and protects the internal components of the water pump. It’s typically made of aluminum, cast iron, or plastic and is bolted directly to the engine block. The housing has an inlet and an outlet for coolant, guiding its flow from the radiator to the engine and back.

- Impeller: The impeller is the heart of the water pump assembly. It is a fan-like component with blades that rotate to create centrifugal force, which pushes coolant through the engine’s cooling system. Impellers are often made from metal or composite materials for durability.

- Shaft: The impeller is mounted on a central shaft, which connects the water pump to the engine’s crankshaft or timing belt. This shaft rotates the impeller, driving the circulation of the coolant through the system.

- Bearing Assembly: The shaft is supported by bearings that allow it to rotate smoothly and with minimal friction. The bearings also ensure that the shaft remains properly aligned while preventing excessive wear on the pump.

- Mechanical Seal: A critical seal is located between the impeller and the shaft to prevent coolant from leaking out of the pump and into other parts of the engine. This seal keeps the coolant inside the pump under pressure and protects the engine from potential damage caused by leaks.

- Pulley: The pulley connects the water pump assembly to the engine’s drive belt or timing belt system. It allows the pump to be driven by the engine, typically at a speed proportional to the engine’s RPMs. Some water pumps are driven by the timing belt, while others are driven by the accessory belt.

2. Functions of the Engine Water Pump Assembly

The engine water pump assembly plays an indispensable role in the vehicle’s cooling system by ensuring a continuous flow of coolant. Key functions include:

- Coolant Circulation: The primary function of the water pump is to draw coolant from the radiator and push it through the engine’s water jackets, which are passages surrounding the engine cylinders. As the coolant absorbs heat from the engine, it is returned to the radiator where it is cooled before being recirculated.

- Regulating Engine Temperature: By circulating coolant, the water pump ensures that the engine operates within its optimal temperature range. An overheated engine can cause severe damage to the cylinder head, pistons, and gaskets, while an engine that runs too cool can suffer from poor fuel efficiency.

- Supporting the Thermostat Function: The water pump works in tandem with the engine’s thermostat, which regulates the flow of coolant based on the engine’s temperature. When the engine is cold, the thermostat remains closed, limiting the flow of coolant. As the engine heats up, the thermostat opens, allowing the water pump to circulate coolant freely.

3. Benefits of the Engine Water Pump Assembly

A properly functioning engine water pump offers several key benefits that directly impact engine performance, efficiency, and longevity:

- Prevents Overheating: The water pump’s primary benefit is preventing the engine from overheating. By circulating coolant through the engine, it dissipates the heat generated during combustion and helps maintain the ideal operating temperature.

- Promotes Optimal Engine Performance: Maintaining the right engine temperature ensures that the engine performs efficiently. When the engine stays within its ideal temperature range, fuel combustion is more efficient, resulting in better acceleration, power output, and overall performance.

- Extends Engine Life: Engine components are highly sensitive to temperature. By regulating engine temperature, the water pump prevents thermal stress on components such as the cylinder head, pistons, and valves. This reduces wear and tear, prolonging the engine’s life and preventing costly repairs.

- Improves Fuel Efficiency: A properly regulated engine temperature ensures optimal fuel combustion, improving fuel economy. Overheating or undercooling can lead to inefficient fuel use, which increases consumption and emissions.

- Reduces Engine Wear: By circulating coolant evenly throughout the engine, the water pump reduces localized heat spots that could cause warping, cracking, or distortion in engine parts. This even heat distribution helps to reduce engine wear and mechanical fatigue.

4. Common Issues with Engine Water Pump Assemblies

While engine water pumps are designed to last tens of thousands of miles, they can eventually fail due to wear, contamination, or improper maintenance. Some common issues include:

- Coolant Leaks: One of the most common signs of water pump failure is coolant leakage. This usually occurs when the mechanical seal around the shaft or the gasket between the housing and engine block fails. Leaks can lead to a drop in coolant levels, causing the engine to overheat.

- Worn Bearings: The water pump’s bearings can wear out over time, especially under harsh driving conditions. When bearings fail, the shaft may wobble, causing the impeller to become misaligned, reducing the pump’s ability to circulate coolant effectively. Worn bearings also produce a grinding or whining noise from the engine bay.

- Impeller Damage: The impeller, responsible for pushing coolant, can become corroded or damaged over time, particularly if low-quality or contaminated coolant is used. A worn or damaged impeller will not move coolant effectively, leading to overheating.

- Belt or Pulley Issues: The water pump relies on the engine’s drive belt or timing belt for power. A loose, cracked, or broken belt can cause the pump to stop working altogether. Additionally, a faulty pulley may cause slippage, reducing the efficiency of the water pump.

- Overheating: A failing water pump may not circulate coolant effectively, leading to engine overheating. Symptoms of overheating include rising temperature gauge readings, steam from the engine bay, and poor engine performance.

5. Maintenance of the Engine Water Pump Assembly

To ensure the longevity and proper function of the water pump, regular maintenance is essential. Key maintenance practices include:

- Regular Coolant Changes: Old or contaminated coolant can corrode the water pump’s impeller and seals, leading to premature failure. Always use the manufacturer-recommended coolant type and change it at the specified intervals to keep the system clean and free from debris.

- Inspect for Leaks: Regularly check the area around the water pump for signs of coolant leaks. Even small leaks can eventually lead to a drop in coolant levels, causing the engine to overheat.

- Monitor Engine Temperature: Keep an eye on the engine temperature gauge while driving. If the engine is running hotter than normal, it may indicate a problem with the water pump. Address any temperature irregularities immediately to avoid serious engine damage.

- Belt and Pulley Inspection: Periodically inspect the drive belt and pulley for signs of wear or damage. A loose or frayed belt can reduce the water pump’s efficiency or cause it to fail completely.

- Check for Unusual Noises: Listen for any grinding, squealing, or whining noises from the water pump area. These sounds can indicate worn bearings or a damaged impeller. Address these issues promptly to prevent total water pump failure.

- Replace the Pump When Necessary: Most water pumps are designed to last between 60,000 to 100,000 miles, but they can fail sooner under harsh conditions. If the water pump is showing signs of wear or failure, it’s best to replace it during routine maintenance, such as when replacing the timing belt.

6. Conclusion

The engine water pump assembly is one of the most important components in a vehicle’s cooling system. By circulating coolant through the engine and radiator, it helps regulate engine temperature, prevents overheating, and supports optimal performance. The pump’s key parts include the housing, impeller, shaft, bearings, seal, and pulley, all of which work in concert to ensure smooth and efficient coolant flow.

Proper maintenance of the water pump is essential for keeping the cooling system functioning effectively. Regular inspections, coolant changes, and timely replacement of worn components can prevent costly repairs and extend the life of both the pump and the engine. Ultimately, a well-maintained water pump ensures that your engine runs efficiently, performs at its best, and avoids the costly consequences of overheating.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.