-7%

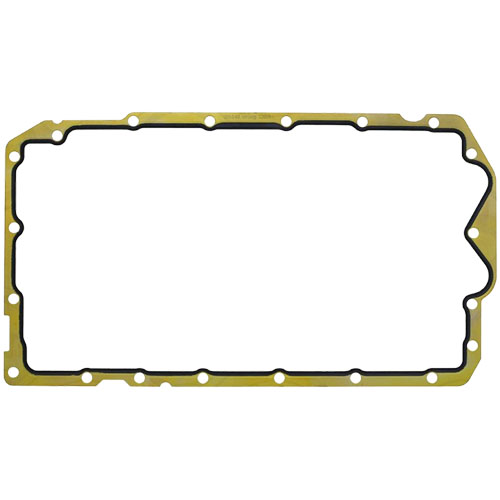

Get BMW X1 E84 Engine Oil Pan Gasket Seal 11137511224 in Kenya

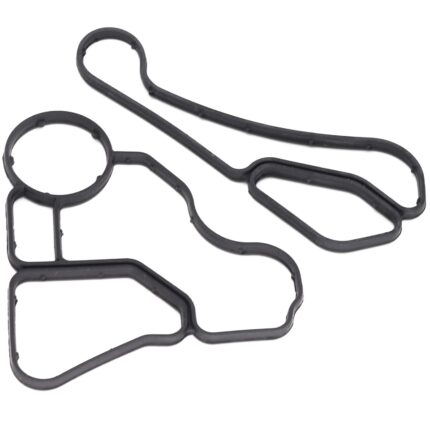

The oil cooler gasket is a small yet crucial component of a vehicle’s lubrication and cooling system. It acts as a seal between the engine oil cooler and the engine block or adapter, preventing oil and coolant leaks. Despite its relatively simple function, a faulty oil cooler gasket can lead to severe engine problems, including oil leaks, overheating, and reduced lubrication efficiency.

In this comprehensive guide, we will explore the function, types, importance, common failure symptoms, replacement process, and maintenance tips for an oil cooler gasket.

1. What is an Oil Cooler Gasket?

An oil cooler gasket is a specially designed seal made of rubber, silicone, metal, or composite material that ensures a leak-proof connection between the engine oil cooler and the engine block or the cooler housing.

Since the oil cooler helps regulate engine oil temperature, the gasket plays a critical role in keeping the system sealed, preventing oil and coolant mixing, which could otherwise lead to severe engine damage.

The oil cooler gasket must withstand extreme temperatures, pressure, and exposure to oil and coolant, making it a vital component for ensuring proper lubrication and cooling.

2. Function of the Oil Cooler Gasket

The oil cooler gasket serves three primary functions:

2.1 Sealing the Oil Cooler Connection

- The oil cooler gasket prevents engine oil from leaking out of the oil cooler assembly.

- It ensures that engine oil flows only through the oil cooler and back into the lubrication system without escaping.

2.2 Preventing Oil and Coolant Mixing

- Some oil coolers are integrated into the cooling system, meaning both oil and coolant flow through separate channels.

- The gasket prevents these two fluids from mixing, which could lead to oil contamination, overheating, and severe engine damage.

2.3 Maintaining Proper Lubrication and Cooling

- By ensuring that oil is effectively cooled and returned to the engine, the gasket helps in reducing friction and preventing excessive wear on engine components.

3. Importance of the Oil Cooler Gasket

3.1 Prevents Oil Leaks

A damaged gasket can cause oil to leak from the cooler, leading to low oil levels, which can cause engine damage due to insufficient lubrication.

3.2 Maintains Cooling Efficiency

If the oil cooler gasket fails, hot engine oil may bypass the cooling system, leading to overheating and increased wear on engine parts.

3.3 Protects Against Engine Contamination

A failing gasket can allow coolant and oil to mix, leading to oil contamination. This can cause:

- Engine sludge buildup

- Reduced lubrication efficiency

- Blocked oil passages

3.4 Prevents Engine Overheating

If the gasket leaks coolant, the engine cooling system may become inefficient, leading to overheating and potential engine failure.

4. Types of Oil Cooler Gaskets

Oil cooler gaskets vary based on material composition and design. The most common types include:

4.1 Rubber or Silicone Gaskets

- Found in many modern vehicles.

- Resistant to heat and oil exposure.

- Flexible and provides a strong leak-proof seal.

4.2 Metal Gaskets

- Used in high-performance engines or heavy-duty vehicles.

- More durable but requires precise installation to prevent leaks.

4.3 Composite Gaskets

- Made from a combination of rubber, metal, and fiber materials.

- Designed for high-temperature resistance and longevity.

4.4 O-Ring Seals

- Found in some oil cooler assemblies.

- Made of rubber or silicone and provides a flexible, secure seal.

5. Common Symptoms of a Faulty Oil Cooler Gasket

A failing oil cooler gasket can cause various issues, including leaks, overheating, and engine damage. Some common symptoms include:

5.1 Oil Leaks

- One of the most obvious signs of a failing gasket.

- Oil may leak from the oil cooler housing or engine block.

- You may notice oil puddles under the vehicle.

5.2 Coolant Leaks

- If the gasket seals both oil and coolant passages, a failure can cause coolant to leak.

- Coolant leaks can lead to engine overheating.

5.3 Oil Contamination (Milky Oil)

- If coolant enters the oil system, it can turn the oil milky or frothy.

- Contaminated oil reduces lubrication and can cause engine wear.

5.4 Overheating

- If the gasket fails, the oil cooler may not function properly, causing the engine to overheat.

- Warning lights on the dashboard may indicate high engine temperatures.

5.5 Low Oil Pressure

- A leaking gasket can cause a drop in oil pressure, leading to poor lubrication.

- This can result in engine knocking or ticking noises.

6. Causes of Oil Cooler Gasket Failure

Several factors can lead to oil cooler gasket failure, including:

6.1 Heat and Pressure

- The gasket is constantly exposed to high temperatures and pressure, causing it to wear out over time.

6.2 Poor Installation

- Incorrect installation can cause improper sealing, leading to oil or coolant leaks.

6.3 Aging and Material Degradation

- Over time, the gasket hardens, cracks, or shrinks, losing its ability to form a proper seal.

6.4 Contaminants in Oil or Coolant

- Dirty oil or coolant can cause premature wear on the gasket.

6.5 Engine Vibrations

- Constant engine vibrations can loosen or damage the gasket, leading to leaks.

7. Oil Cooler Gasket Replacement Process

If your oil cooler gasket is failing, replacing it as soon as possible is crucial to prevent engine damage. Here’s a general step-by-step guide to replacing an oil cooler gasket:

7.1 Gather Tools and Parts

- New oil cooler gasket

- Socket wrenches

- Screwdrivers

- Torque wrench

- Drain pan

- Coolant and engine oil

7.2 Drain the Engine Oil and Coolant

- Place a drain pan under the vehicle.

- Remove the oil drain plug and let the oil drain completely.

- If the oil cooler is connected to the cooling system, drain the coolant as well.

7.3 Remove the Oil Cooler

- Locate the oil cooler (usually mounted on the engine block or near the radiator).

- Unbolt the oil cooler housing.

- Carefully detach the old gasket.

7.4 Clean the Surfaces

- Use a gasket scraper to remove old gasket residue.

- Clean the mounting surfaces with brake cleaner or degreaser.

7.5 Install the New Gasket

- Place the new gasket onto the oil cooler.

- Align the oil cooler with the engine block.

- Secure the bolts to the manufacturer’s torque specifications.

7.6 Refill Engine Oil and Coolant

- Refill the engine oil and coolant.

- Start the engine and check for leaks.

7.7 Final Inspection

- Let the engine run for a few minutes.

- Check the oil pressure and temperature gauge.

- Look for any signs of leaks around the oil cooler.

8. Maintenance Tips for Oil Cooler Gaskets

To extend the lifespan of your oil cooler gasket:

- Use high-quality oil and coolant to prevent contamination.

- Check for leaks regularly.

- Replace the gasket at the first sign of failure.

- Avoid overheating by keeping the cooling system in good condition.

- Ensure proper installation during replacement.

Conclusion

The oil cooler gasket is a small but essential component that prevents oil and coolant leaks, ensuring efficient engine cooling and lubrication. A failing gasket can lead to overheating, oil contamination, and engine damage. Regular maintenance and timely replacement are critical to keeping your engine in optimal condition.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.