-20%

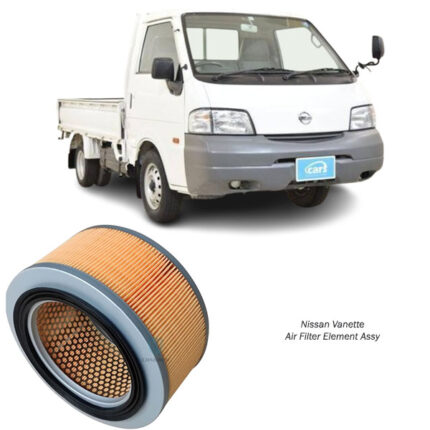

Get Nissan Vannette Air Filter Element Assy 16546-HA300 in Kenya

The air filter element assembly is a crucial part of your vehicle’s engine system. It ensures that clean air reaches the engine for combustion while preventing harmful particles from entering the system. This detailed explanation will cover its function, benefits, components, signs of wear, and maintenance practices.

1. Understanding the Air Filter Element Assembly

What is an Air Filter Element Assembly?

The air filter element assembly consists of a filtering medium housed within a casing that fits into the air intake system of an engine. Its primary purpose is to filter dust, dirt, pollen, and other contaminants from the air before it mixes with fuel in the combustion chamber.

Types of Air Filter Elements

Air filters come in different designs, depending on the vehicle’s make and purpose. Common types include:

- Paper Filters: Made from pleated paper, these are disposable and affordable.

- Foam Filters: Often used in off-road vehicles due to their durability and washable nature.

- Cotton Gauze Filters: These are reusable, high-performance filters often found in sports cars.

- Synthetic Filters: Made from synthetic fibers, these provide high filtration efficiency and are long-lasting.

2. Components of the Air Filter Assembly

Filter Element

The filter material (e.g., paper, foam, or synthetic fibers) traps contaminants while allowing clean air to flow through.

Housing Unit

The air filter is enclosed within a housing that protects it from external elements and helps direct airflow.

Seal or Gasket

A rubber or foam seal ensures a tight fit, preventing unfiltered air from bypassing the filter.

Support Frame

Some filters include a metal or plastic frame to maintain structural integrity and prevent deformation under high airflow.

3. Functions of the Air Filter Assembly

Air Purification

The assembly removes airborne contaminants such as dust, debris, and pollen to ensure clean air reaches the engine.

Protects the Engine

By trapping harmful particles, the air filter prevents engine wear and damage, extending its lifespan.

Ensures Optimal Combustion

Clean air is essential for efficient combustion. The air filter maintains the proper air-to-fuel ratio for optimal engine performance.

Improves Fuel Efficiency

A clean air filter minimizes engine strain, reducing fuel consumption and promoting smoother operation.

4. Benefits of a Well-Maintained Air Filter Assembly

Enhanced Engine Performance

Clean air improves combustion efficiency, resulting in better acceleration and power output.

Fuel Savings

A clogged filter restricts airflow, causing the engine to work harder and consume more fuel. A clean filter improves fuel economy.

Reduced Emissions

Efficient combustion reduces harmful emissions, contributing to a cleaner environment.

Extended Engine Life

By keeping contaminants out of the engine, the air filter assembly minimizes wear on internal components, enhancing their durability.

Improved Driving Experience

A clean air filter ensures smooth engine performance, reducing noise and vibration.

5. Signs of a Faulty or Clogged Air Filter Assembly

Knowing when to replace or clean the air filter can prevent engine problems. Look out for these warning signs:

- Reduced Fuel Efficiency: A clogged filter limits airflow, causing the engine to burn more fuel.

- Decreased Engine Power: Restricted air supply leads to sluggish acceleration and poor performance.

- Black Smoke from the Exhaust: A dirty filter can disrupt the air-to-fuel ratio, causing incomplete combustion.

- Unusual Engine Sounds: A clogged filter may cause the engine to make popping or coughing noises.

- Dirty Filter Appearance: A visual inspection showing accumulated dirt and debris is a clear indication of a clogged filter.

6. Maintenance Tips for the Air Filter Assembly

Follow Replacement Guidelines

Most manufacturers recommend replacing the air filter every 12,000 to 15,000 miles, or as specified in the vehicle’s manual. For vehicles driven in dusty or harsh environments, more frequent replacements may be necessary.

Inspect Regularly

Perform visual inspections during routine maintenance. Check for dirt, damage, or deformation in the filter element.

Clean Reusable Filters

For reusable filters (e.g., foam or cotton gauze), follow the manufacturer’s instructions for cleaning and re-oiling. Avoid using harsh chemicals that can damage the filter material.

Ensure Proper Fit

When replacing the filter, ensure it fits securely within the housing to prevent unfiltered air from entering the engine.

Use High-Quality Filters

Invest in OEM or reputable aftermarket filters designed specifically for your vehicle to ensure proper performance and durability.

Protect the Intake System

Ensure the air intake system is free of cracks or leaks that could allow unfiltered air to bypass the filter.

7. Consequences of Neglecting Air Filter Maintenance

Engine Wear

Unfiltered air allows dirt and debris to enter the engine, causing premature wear of pistons, cylinders, and valves.

Reduced Performance

A clogged filter restricts airflow, leading to sluggish acceleration and diminished power output.

Higher Fuel Consumption

Restricted airflow forces the engine to work harder, increasing fuel usage and costs.

Increased Emissions

Inefficient combustion due to poor air supply can increase harmful emissions, potentially failing emissions tests.

Costly Repairs

Neglected air filter maintenance can lead to severe engine damage, resulting in expensive repairs or replacements.

8. Air Filter Assembly in Different Applications

Passenger Cars

Modern vehicles use high-efficiency air filters to balance performance, durability, and environmental compliance.

Off-Road Vehicles

Off-road and utility vehicles require robust filters, such as foam or dual-stage filters, to handle dusty conditions.

High-Performance Vehicles

Sports cars and high-performance vehicles use advanced filters like cotton gauze to maximize airflow and power output.

Diesel Engines

Diesel engines often feature larger filters with additional layers for enhanced filtration and longer service intervals.

9. Professional Servicing

While basic air filter replacement is a simple task, professional servicing ensures that the entire air intake system is inspected and maintained. Professionals can identify potential issues such as leaks, cracks, or improper installation that may go unnoticed.

10. Air Filter Assembly Innovations

Advancements in air filter technology aim to improve performance and sustainability:

- Nano-Fiber Filters: Offer superior filtration efficiency and durability.

- Eco-Friendly Materials: Biodegradable and recyclable filters reduce environmental impact.

- Smart Filters: Integrated sensors monitor filter condition and notify users when replacement is needed.

Conclusion

The air filter element assembly plays an indispensable role in maintaining engine health and performance. By ensuring clean air reaches the engine, it enhances fuel efficiency, reduces emissions, and prevents costly damage. Regular inspections, timely replacements, and adherence to manufacturer guidelines are essential for optimal performance and longevity.

Investing in high-quality air filters and proper maintenance not only protects your engine but also contributes to a smoother and more efficient driving experience. For any vehicle owner, prioritizing air filter care is a small but vital step toward maintaining a reliable and efficient engine.

Follow us on Facebook for more parts.