-12%

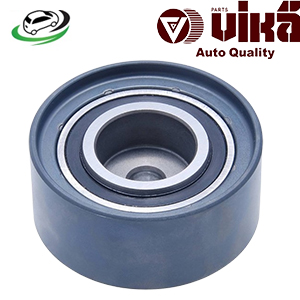

Get AUDI A4 B6 (8E2)/ A4 B8 (8K2)/ A4 B7 (8EC)/ A5 (8T3)/ 6 C6 (4F2)/ Q5 (8RB) / VW Amarok (2HA 2HB S1B S6B S7A S7B)/ Tiguan (5N) Alternator Belt Idler Pully 03G145276

The alternator belt idler pulley is a vital component in an internal combustion engine, responsible for ensuring the smooth operation of the belt-driven systems. It plays a crucial role in regulating the tension and alignment of the serpentine belt or alternator belt, which drives various accessories in the engine, such as the alternator, power steering pump, water pump, and air conditioning compressor.

Understanding the function, benefits, and maintenance of the alternator belt idler pulley is essential for anyone involved in automotive care, whether a car owner, mechanic, or someone working in the auto parts industry. This guide will provide a comprehensive explanation of this component, shedding light on its importance in engine performance and vehicle longevity.

1. Function of the Alternator Belt Idler Pulley

The alternator belt idler pulley is a small, grooved wheel designed to guide the serpentine belt and maintain the appropriate tension within the belt system. It ensures that the belt remains in proper alignment while rotating at high speeds. Here’s how it works:

- Guiding the Belt: As the engine runs, the serpentine belt transfers mechanical energy from the engine’s crankshaft to power several auxiliary components. The idler pulley is positioned to direct and route the belt correctly through the system, ensuring that it stays aligned with each accessory pulley.

- Maintaining Belt Tension: The idler pulley works with other tensioners to keep the belt at an optimal tightness, preventing slack that could lead to slipping, squealing, or even belt failure. This tension is crucial to avoid the belt coming off the pulleys or wearing out prematurely.

- Reducing Vibration and Noise: By keeping the belt under proper tension and alignment, the idler pulley minimizes vibrations that would otherwise cause noise or wear on the belt and pulleys. A well-functioning idler pulley helps ensure the smooth operation of the engine’s accessories.

Without a properly functioning alternator belt idler pulley, the belt could slip off, crack, or break, leading to accessory failure, engine overheating, or a dead battery, as the alternator wouldn’t function effectively.

2. Benefits of a Well-Maintained Alternator Belt Idler Pulley

Maintaining the alternator belt idler pulley in good condition offers several key benefits to vehicle performance and longevity:

a. Extended Serpentine Belt Life

The alternator belt idler pulley ensures the serpentine belt operates under optimal conditions. When the pulley works correctly, it prevents the belt from stretching, fraying, or cracking prematurely. This leads to fewer belt replacements, saving time and money on repairs.

b. Improved Engine Efficiency

The serpentine belt drives several critical components, such as the alternator and water pump, which are essential for keeping the engine running efficiently. A properly functioning idler pulley ensures that these components receive sufficient power from the belt, improving the overall efficiency of the engine.

- Charging the Battery: The alternator relies on the serpentine belt to generate electrical power to charge the vehicle’s battery. If the belt slips due to a faulty pulley, the alternator won’t work effectively, leading to a dead battery.

- Cooling the Engine: The serpentine belt drives the water pump, which circulates coolant through the engine. A poorly functioning idler pulley may cause belt slippage, reducing the efficiency of the cooling system, which could lead to engine overheating.

c. Smooth Operation of Accessories

With the correct belt tension and alignment provided by the idler pulley, the belt-driven accessories, such as the air conditioning compressor, power steering pump, and alternator, work seamlessly. This ensures optimal performance of the vehicle’s air conditioning, power steering, and electrical systems.

d. Reduced Engine Noise

A failing idler pulley can produce squealing or grinding noises due to misalignment or lack of proper tension. Replacing a worn idler pulley restores the quiet and smooth operation of the engine, enhancing the overall driving experience.

3. Symptoms of a Failing Alternator Belt Idler Pulley

While the alternator belt idler pulley is designed for long-term performance, it is not immune to wear and tear. Several symptoms may indicate that the pulley is failing or needs replacement:

a. Squealing or Grinding Noises

One of the most common signs of a failing idler pulley is a high-pitched squealing sound coming from the engine, especially when the vehicle is started or accelerating. This occurs due to a misaligned or worn-out pulley that is not properly guiding the belt. Grinding noises may also indicate that the pulley’s internal bearings are worn out.

b. Belt Slippage

If the idler pulley fails to maintain adequate tension, the serpentine belt may begin to slip. This can cause intermittent accessory failure, such as loss of power steering, malfunctioning air conditioning, or electrical system issues due to an underperforming alternator.

c. Visible Belt Wear

A damaged or misaligned idler pulley can lead to abnormal wear patterns on the serpentine belt. If the belt shows signs of fraying, cracking, or glazing, it could be due to an issue with the pulley that needs immediate attention.

d. Engine Overheating

In some cases, a failing idler pulley can prevent the belt from adequately driving the water pump, which circulates coolant through the engine. This can lead to engine overheating, which is a serious issue that requires prompt repairs.

4. Maintenance and Replacement Tips for the Alternator Belt Idler Pulley

a. Regular Inspection

As part of routine maintenance, the alternator belt idler pulley should be inspected regularly for signs of wear or damage. Check for the following:

- Pulley Wear: Inspect the pulley for visible damage, such as cracks, chips, or a rough surface, which can affect the belt’s alignment.

- Bearings: Spin the pulley manually to listen for any unusual noise or feel for resistance, which could indicate worn-out bearings.

b. Belt Condition

While inspecting the idler pulley, also examine the serpentine belt for any signs of wear or damage. If the belt appears worn, replace it along with the pulley to avoid future issues.

c. Timely Replacement

If any signs of pulley failure are noticed, it is crucial to replace the idler pulley as soon as possible. Delaying replacement can lead to severe damage to the belt and associated accessories, potentially causing more costly repairs.

d. OEM vs. Aftermarket Parts

When replacing the alternator belt idler pulley, consider whether to use an original equipment manufacturer (OEM) part or an aftermarket option. OEM parts are often recommended for their precise fit and compatibility, but high-quality aftermarket parts may provide cost savings without compromising performance.

5. Conclusion

The alternator belt idler pulley is a small but essential component that ensures the smooth and efficient operation of a vehicle’s engine. By maintaining proper belt tension and alignment, the idler pulley supports critical engine functions such as charging the battery, cooling the engine, and powering accessories like air conditioning and power steering.

Regular inspection, timely replacement, and proper maintenance of the alternator belt idler pulley can extend the life of the serpentine belt, reduce engine noise, and prevent accessory failures. Given its importance, car owners and mechanics should pay close attention to the condition of the idler pulley as part of their regular vehicle maintenance routine.

Follow us on Facebook for more parts.

Reviews

Clear filtersThere are no reviews yet.