Description

Get AUDI B5 A4 Crankcase Breather Tube 06A103213F in Kenya

The crankcase breather tube is a critical component in an internal combustion engine’s ventilation system. Although it might seem like a minor part, the breather tube plays a significant role in engine health, performance, and emissions control. This comprehensive analysis delves into the function, structure, common problems, and maintenance of the crankcase breather tube, highlighting its importance in modern engines.

1. Overview and Role of the Crankcase Breather Tube

The crankcase is a sealed chamber in the engine that houses the crankshaft and other moving parts. During engine operation, combustion gases can leak past the piston rings into the crankcase, creating what are known as blow-by gases. These gases are composed of unburned fuel, air, water vapor, and other combustion byproducts. If these gases are not properly vented, they can cause excessive pressure to build up within the crankcase, leading to a host of issues including oil leaks, increased oil consumption, and even engine damage.

The crankcase breather tube is responsible for venting these blow-by gases out of the crankcase. It is an integral part of the Positive Crankcase Ventilation (PCV) system, which manages the flow of these gases to ensure that they are safely re-burned in the engine, rather than being released into the atmosphere. This process not only reduces harmful emissions but also helps maintain proper engine pressure, ensuring the engine operates efficiently and reliably.

2. Structure and Functionality

The crankcase breather tube is typically made from durable materials like rubber, silicone, or plastic, which are designed to withstand the harsh environment of the engine bay, including exposure to high temperatures, oil, and chemical vapors.

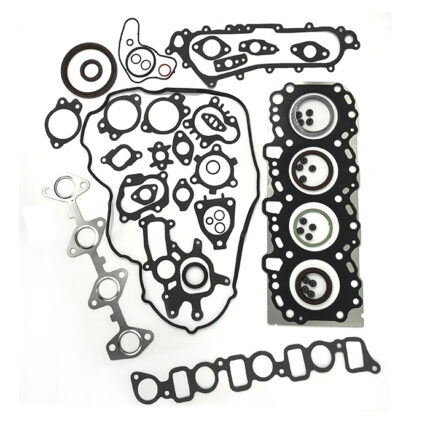

2.1. Components of the Crankcase Ventilation System

- Crankcase: The lower part of the engine block that houses the crankshaft and other moving parts.

- PCV Valve: A one-way valve that regulates the flow of blow-by gases from the crankcase to the intake manifold.

- Crankcase Breather Tube: The conduit through which the gases are vented from the crankcase, either into the air intake system or directly into the intake manifold, depending on the engine design.

- Oil Separator (in some engines): A device that removes oil mist from the blow-by gases before they are recirculated.

2.2. Operation of the Crankcase Breather Tube

The breather tube works as part of a closed-loop system to ensure that blow-by gases are safely vented and re-burned in the engine. Here’s how it functions:

- Ventilation: As the engine runs, blow-by gases accumulate in the crankcase, increasing pressure. The breather tube allows these gases to escape from the crankcase, preventing pressure build-up that could damage seals and gaskets.

- Gas Recirculation: The gases that exit through the breather tube are usually routed into the intake manifold or air intake system, where they are mixed with fresh air and fuel. These gases are then drawn into the cylinders and re-burned during the combustion process.

- Emission Control: By recirculating the blow-by gases rather than venting them into the atmosphere, the breather tube helps reduce harmful emissions, including hydrocarbons and carbon monoxide.

3. Importance of the Crankcase Breather Tube

The crankcase breather tube is crucial for several reasons:

- Pressure Regulation: It helps maintain optimal pressure levels within the crankcase, preventing issues like oil leaks and gasket failures caused by excessive pressure.

- Oil Quality Maintenance: By venting blow-by gases, the breather tube prevents these gases from contaminating the engine oil. Contaminated oil can lose its lubricating properties, leading to increased engine wear and potentially catastrophic failure.

- Emission Control: The breather tube plays a vital role in reducing emissions by ensuring that blow-by gases are burned rather than released into the environment.

- Engine Performance: A properly functioning breather tube contributes to smoother engine operation by preventing pressure imbalances that can lead to poor performance, rough idling, or stalling.

4. Common Issues and Symptoms

While the crankcase breather tube is designed for durability, it can develop issues over time that may impact engine performance. Here are some common problems:

- Clogging: The breather tube can become clogged with oil sludge, carbon deposits, or debris. This blockage can prevent the proper flow of gases, leading to increased crankcase pressure, oil leaks, and reduced engine performance. A clogged breather tube can also cause the engine to consume more oil than usual.

- Cracks or Deterioration: Exposure to high temperatures and engine chemicals can cause the breather tube to crack or deteriorate over time. A cracked tube can allow unmetered air into the intake system, leading to a lean air-fuel mixture, which can cause rough idling, poor acceleration, and increased emissions.

- Collapsed Tube: Under certain conditions, such as extreme vacuum pressure, the breather tube may collapse, restricting the flow of gases. This can cause symptoms similar to a clogged tube, including increased crankcase pressure and oil leaks.

- Oil Contamination: In some cases, a malfunctioning PCV system can allow oil to be drawn into the breather tube and intake manifold, leading to oil contamination in the air intake system. This can cause the engine to run poorly and produce excessive smoke.

5. Diagnosis and Troubleshooting

Diagnosing issues with the crankcase breather tube typically involves a combination of visual inspection and functional testing. Here’s a step-by-step guide:

5.1. Visual Inspection

- Check for Cracks or Deterioration: Visually inspect the breather tube for any signs of cracks, splits, or general deterioration. Pay close attention to areas where the tube bends or connects to other components, as these are common points of failure.

- Inspect for Blockages: If the tube is accessible, remove it and inspect the interior for any signs of blockage, such as sludge or carbon deposits. A clogged tube will need to be cleaned or replaced.

- Look for Oil Leaks: Check the connections at both ends of the breather tube for oil leaks, which could indicate a loose connection or a damaged tube.

5.2. Functional Testing

- Check Engine Performance: Pay attention to any symptoms of engine performance issues, such as rough idling, stalling, or poor acceleration. These could be signs of a problem with the breather tube.

- Test for Excessive Crankcase Pressure: If you suspect that the breather tube is clogged or blocked, a mechanic can perform a crankcase pressure test. This involves measuring the pressure in the crankcase while the engine is running to ensure it is within the normal range.

6. Maintenance and Replacement

Regular maintenance of the crankcase breather tube is essential to ensure the proper operation of the engine’s ventilation system. Here are some maintenance tips:

6.1. Cleaning

If the breather tube is clogged but still in good condition, it can often be cleaned rather than replaced:

- Remove the Tube: Carefully disconnect the breather tube from the crankcase and intake system. Make a note of its orientation for reinstallation.

- Clean the Tube: Use a suitable solvent, such as carburetor cleaner or brake cleaner, to dissolve any sludge or carbon buildup inside the tube. A soft brush can help remove stubborn deposits.

- Dry the Tube: Allow the tube to dry completely before reinstalling it. Ensure that no solvent residue remains inside the tube, as this could damage the engine.

- Reinstall the Tube: Reconnect the tube, ensuring it is securely attached and free from any kinks or bends.

6.2. Replacement

If the tube is damaged or excessively clogged, it should be replaced. The process is generally straightforward:

- Locate the Breather Tube: Refer to the vehicle’s service manual to locate the breather tube and identify any components that need to be removed to access it.

- Remove the Old Tube: Disconnect the tube from its connections at both ends, loosening any clamps or fasteners as needed.

- Install the New Tube: Fit the new tube in place, ensuring it is the correct length and diameter for the engine. Secure it with the appropriate clamps or fasteners.

- Test the System: Start the engine and let it run for a few minutes. Check for any leaks or abnormal engine behavior to ensure the new tube is functioning correctly.

7. Impact on Engine Longevity and Performance

A well-maintained crankcase breather tube is essential for the longevity and performance of the engine. By ensuring proper ventilation and preventing the build-up of harmful gases in the crankcase, the breather tube helps:

- Extend Engine Life: Preventing excessive crankcase pressure and oil contamination reduces wear and tear on engine components, helping to extend the life of the engine.

- Improve Fuel Efficiency: A properly functioning breather tube helps maintain the correct air-fuel mixture, leading to better fuel efficiency.

- Reduce Emissions: By recirculating blow-by gases and preventing them from being released into the atmosphere, the breather tube plays a key role in reducing vehicle emissions.

8. Advances in Crankcase Ventilation Technology

As automotive technology advances, so too does the design and functionality of crankcase ventilation systems. Some modern advancements include:

- Enhanced PCV Systems: Modern PCV systems are designed to be more efficient, with features like heated PCV valves to prevent freezing in cold climates and variable flow rates to match engine load conditions.

- Integrated Oil Separators: Some engines now include integrated oil separators that remove oil mist from the blow-by gases before they are recirculated, reducing oil consumption and preventing contamination of the intake system.

- Closed-Loop Systems: Most modern engines use closed-loop ventilation systems that capture all blow-by gases and prevent them from escaping into the atmosphere, improving emissions control.

- Follow us on Facebook for more parts.