-20%

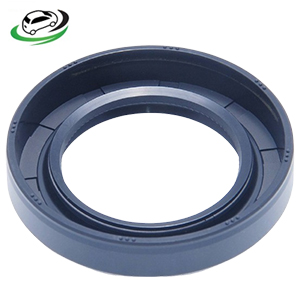

Get Genuine Drive Shaft Oil Seal 9031138032

The drive shaft oil seal, also known simply as the oil seal or axle seal, is a critical component in a vehicle’s drivetrain system. It is located at the point where the drive shaft connects to the differential or transmission, sealing the opening to prevent lubricating oil from leaking out and contaminants from entering. This article explores the function, importance, materials, common issues, replacement process, and maintenance of drive shaft oil seals.

Function and Importance

The primary function of the drive shaft oil seal is to maintain a sealed barrier between the transmission or differential housing and the outside environment. Its key roles include:

- Sealing: Prevents lubricating oil from leaking out of the transmission or differential, ensuring that the components remain properly lubricated for smooth operation.

- Contamination Prevention: Blocks contaminants such as dirt, dust, and moisture from entering the transmission or differential housing. This protects internal components from wear and damage caused by abrasive particles or corrosion.

- Retention of Pressure: Helps to maintain internal pressure within the transmission or differential housing, which is crucial for proper lubricant circulation and cooling.

Materials

Drive shaft oil seals are typically made from materials that offer flexibility, durability, and resistance to oil and temperature extremes commonly found in automotive applications:

- Nitrile Rubber (Buna-N): Commonly used for its excellent resistance to oils, fuels, and hydraulic fluids. Nitrile rubber seals are cost-effective and widely used in automotive seals.

- Fluoroelastomer (Viton): Offers superior resistance to heat, oils, fuels, and a wide range of chemicals. Viton seals are more expensive but provide extended service life in demanding environments.

- Polyacrylate (ACM): Known for its good resistance to heat and petroleum-based oils. ACM seals are used in applications where moderate sealing performance is required at a lower cost than fluoroelastomers.

Common Issues

Over time, drive shaft oil seals can wear out or become damaged due to various factors, leading to several potential issues:

- Oil Leaks: The most common symptom of a failing drive shaft oil seal is oil leaking from the transmission or differential housing. This may result in oil spots or puddles under the vehicle, especially near the drive shaft.

- Contaminant Ingress: A compromised seal can allow dirt, dust, and moisture to enter the transmission or differential housing. This can lead to accelerated wear of internal components and potential fluid contamination.

- Reduced Lubrication: Oil leaks can lead to insufficient lubrication of gears, bearings, and other moving parts within the transmission or differential, causing increased friction and wear.

- Noise and Vibration: Improper sealing can result in abnormal noise or vibration from the drivetrain, especially during acceleration or deceleration.

- Overheating: Insufficient lubrication due to seal failure can cause the transmission or differential to overheat, potentially leading to more severe damage and costly repairs.

Replacement and Maintenance

Replacing a drive shaft oil seal is a critical maintenance task that should be performed promptly if signs of seal wear or leakage are detected:

- Diagnostic Inspection: If oil leakage or drivetrain issues are observed, conduct a visual inspection around the drive shaft connection to the transmission or differential. Look for signs of oil residue or wetness indicating a leak.

- Preparation: Park the vehicle on a level surface and ensure it is safely supported. Disconnect the battery to prevent accidental starts.

- Access and Removal: Depending on the vehicle design, access to the drive shaft oil seal may require removing components such as the drive shaft, axle shaft, or differential cover.

- Seal Replacement: Carefully remove the old seal using appropriate tools, taking care not to damage the surrounding components. Clean the sealing surface thoroughly to ensure a proper seal for the new oil seal.

- Installation: Install the new oil seal into the designated housing, ensuring it is seated evenly and securely. Use a seal installation tool or a socket of appropriate size to press the seal into place without damaging it.

- Reassembly: Carefully reinstall any components removed to access the oil seal, such as the drive shaft or differential cover. Ensure all bolts and fittings are tightened to the manufacturer’s specifications.

- Testing: Start the engine and monitor for any signs of oil leakage or abnormal noise. Check the area around the oil seal for leaks and verify that the drivetrain operates smoothly without vibration or unusual sounds.

Follow us on Facebook for more parts.