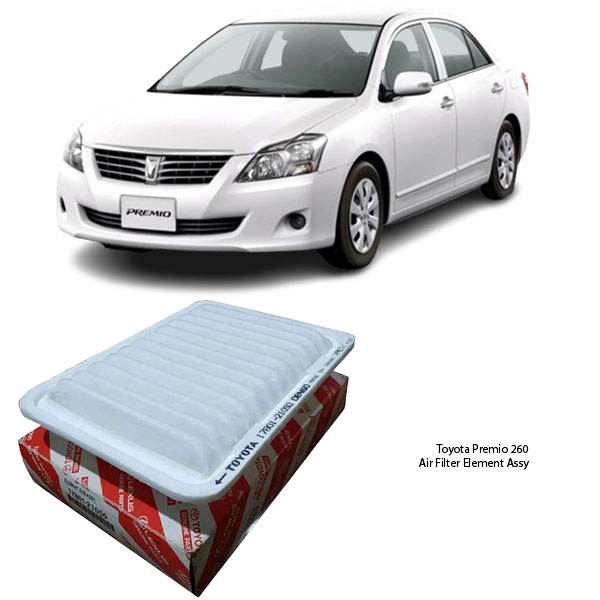

Get Toyota Premio 260 Air Filter Element Assy 17801-21050 in Kenya

Brake pads are essential components of a vehicle’s braking system, responsible for generating the friction needed to slow down or stop the vehicle. They work in conjunction with brake rotors (discs) and calipers. When the brake pedal is pressed, hydraulic pressure forces the brake pads against the rotating brake rotors, creating friction that converts kinetic energy into heat. This process ultimately slows down and stops the vehicle. Brake pads are made from various materials, each offering different performance characteristics and durability.

Functions of Brake Pads

Brake pads serve several critical functions within a vehicle’s braking system:

- Friction Generation: The primary function of brake pads is to create friction against the brake rotors. This friction slows down the rotation of the wheels and brings the vehicle to a stop.

- Heat Dissipation: Brake pads are designed to dissipate the heat generated during braking. Effective heat management prevents overheating of the braking system and ensures consistent performance under various driving conditions.

- Noise Reduction: High-quality brake pads are engineered to minimize noise during braking. Features such as chamfers, slots, and shims help reduce vibrations and prevent squealing or squeaking noises.

- Durability: Brake pads are engineered to withstand the high temperatures and pressures generated during braking. They are designed to wear evenly and provide reliable performance over thousands of miles.

Types of Brake Pads

There are several types of brake pads available, each with its own advantages and considerations:

- Non-Metallic Organic Brake Pads: Made from organic materials such as rubber, glass, and Kevlar, bound together with resin. These pads are quiet, produce less dust, and are gentle on brake rotors. They are suitable for everyday driving but may wear faster under heavy use.

- Semi-Metallic Brake Pads: Contain metal fibers (steel, iron, copper) mixed with organic materials. Semi-metallic pads offer excellent braking performance, durability, and heat dissipation. However, they can be noisy and produce more brake dust.

- Low-Metallic NAO (Non-Asbestos Organic) Brake Pads: These pads contain a small amount of metal (typically around 10-30%), combined with organic materials. Low-metallic NAO pads provide improved braking performance and durability compared to organic pads. They can be noisier and produce more dust than non-metallic organic pads.

- Ceramic Brake Pads: Made from ceramic fibers, nonferrous filler materials, and bonding agents. Ceramic pads offer superior braking performance, excellent heat dissipation, and reduced noise and dust compared to other types. They are ideal for high-performance vehicles and everyday driving.

Signs of Worn or Failing Brake Pads

Recognizing the signs of worn or failing brake pads is crucial for maintaining vehicle safety and performance:

- Squealing or Squeaking Noises: High-pitched noises during braking often indicate that the brake pads are worn down to the wear indicators. These are small metal tabs designed to produce noise when the pads are nearing the end of their life.

- Grinding or Metal-on-Metal Noise: If you hear a grinding noise during braking, it usually means that the brake pads have completely worn down, and the metal backing of the pads is contacting the brake rotors. This can cause significant damage to the rotors and other brake components.

- Reduced Braking Performance: If the vehicle takes longer to come to a stop or the brake pedal feels soft or spongy, it may indicate worn brake pads or air in the brake lines.

- Vibration or Pulsation: A pulsating or vibrating brake pedal when applying brakes could indicate warped brake rotors, unevenly worn brake pads, or problems with the brake calipers.

- Thin Brake Pads: Visual inspection through the wheel spokes can reveal the thickness of the brake pads. If the pads are less than 1/4 inch thick, they should be replaced promptly.

Maintenance and Replacement

Maintaining and replacing brake pads is essential for ensuring optimal braking performance and vehicle safety:

- Regular Inspection: Periodically inspect brake pads for wear and tear. Check the thickness of the pads and look for signs of uneven wear or damage.

- Timely Replacement: Replace brake pads according to the manufacturer’s recommended intervals or when signs of wear are evident. Delaying replacement can lead to damage to other brake components and compromise braking performance.

- Quality Replacement Parts: Use high-quality brake pads that meet or exceed OEM specifications. Quality pads ensure reliable performance, reduced noise, and longer lifespan.

- Professional Installation: If you are not experienced with brake systems, have a professional mechanic install the new brake pads. Proper installation is crucial for safety and optimal braking performance.

Replacement Process

Replacing brake pads involves several steps and may vary depending on the vehicle’s make and model:

- Lift and Secure the Vehicle: Use a jack to lift the vehicle and secure it with jack stands. Remove the wheels to access the brake components.

- Remove the Old Brake Pads: Depending on the brake system design, you may need to unbolt the brake caliper and carefully remove the old brake pads. Take note of any clips, shims, or hardware that needs to be transferred to the new pads.

- Prepare the Caliper and Install New Pads: Clean the brake caliper and rotor surfaces with brake cleaner. Install the new brake pads into the caliper bracket or housing, ensuring they are seated correctly.

- Reassemble and Test: Reinstall the brake caliper over the new pads and rotor. Secure the caliper bolts to the manufacturer’s torque specifications. Reinstall the wheels, lower the vehicle, and perform a test drive to ensure proper brake operation.

Follow us on Facebook for more parts.