-8%

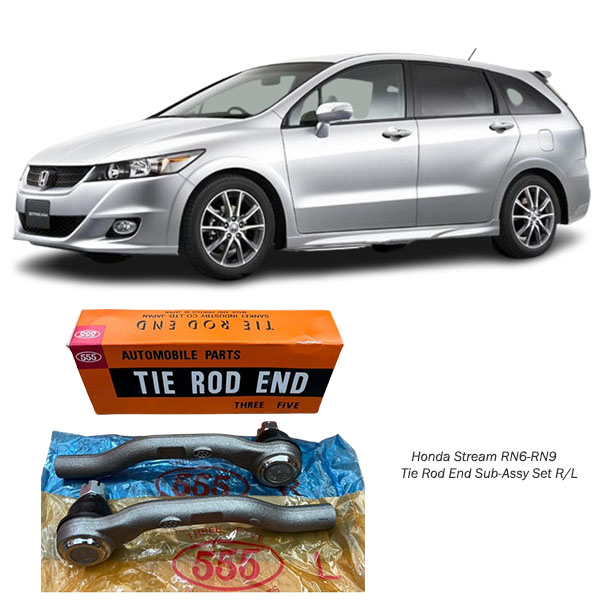

Get Honda Stream RN6-RN9 Tie Rod End Sub-Assy Set R/L SEH331 in Kenya

The tie rod end sub-assembly, commonly referred to as the tie rod end, is a crucial component of a vehicle’s steering system. This assembly consists of the right-hand (R) and left-hand (L) tie rod ends, which connect the steering linkage or rack-and-pinion system to the steering knuckle. These components work in harmony to facilitate smooth, precise, and safe steering. In this detailed guide, we will explore the functions, benefits, types, signs of wear, maintenance practices, and replacement procedures for tie rod ends.

What is a Tie Rod End Sub-Assembly?

The tie rod end sub-assembly is a part of the steering system designed to transmit motion and force from the steering rack to the wheels, enabling directional control of the vehicle.

Each tie rod end consists of:

- Ball Joint

- Allows for smooth rotational and pivoting movements to accommodate the suspension’s range of motion.

- Threaded Rod

- Connects the tie rod end to the steering rack and allows for adjustment during wheel alignment.

- Housing and Protective Boot

- Encases the ball joint and protects it from dirt, debris, and moisture.

A complete sub-assembly includes both the right and left tie rod ends, which ensure balanced and synchronized steering.

Functions of Tie Rod Ends

- Steering Control

- Tie rod ends transfer the rotational motion of the steering wheel to the wheels, enabling directional changes.

- Absorbing Road Impact

- They act as flexible connectors, accommodating suspension movement and road imperfections while maintaining steering stability.

- Alignment Maintenance

- The threaded design allows for precise adjustments during wheel alignment, ensuring even tire wear and optimal vehicle handling.

- Safety Assurance

- A functional tie rod end ensures accurate and responsive steering, which is critical for safe driving.

Benefits of High-Quality Tie Rod Ends

- Improved Steering Precision

- High-quality tie rod ends enhance responsiveness, making the vehicle easier to control, especially during sharp turns or at high speeds.

- Reduced Wear and Tear

- Durable materials and construction minimize wear, extending the lifespan of the steering system and tires.

- Enhanced Safety

- Reliable tie rod ends prevent steering failures, reducing the risk of accidents caused by loss of control.

- Smooth Driving Experience

- They contribute to stable and smooth handling by absorbing vibrations and road shocks.

- Cost Efficiency

- Investing in premium tie rod ends reduces the frequency of replacements and minimizes long-term maintenance costs.

Types of Tie Rod Ends

- Inner Tie Rod Ends

- Connect directly to the steering rack or center link.

- Function as the primary link between the steering system and outer tie rod ends.

- Outer Tie Rod Ends

- Connect the inner tie rod ends to the steering knuckle.

- Responsible for transferring motion to the wheels.

- Adjustable vs. Non-Adjustable

- Adjustable: Common in modern vehicles, allowing for precise alignment adjustments.

- Non-Adjustable: Found in some older models, with fixed geometry.

- OEM vs. Aftermarket

- OEM (Original Equipment Manufacturer): Matches the original specifications and quality.

- Aftermarket: Offers a variety of designs and materials, often at a lower cost.

Signs of Tie Rod End Wear

- Loose or Unresponsive Steering

- Excessive play or vagueness in the steering system can indicate worn tie rod ends.

- Uneven Tire Wear

- Misaligned tie rod ends can cause one side of the tire to wear faster than the other.

- Clunking or Knocking Noise

- Worn tie rod ends may produce noise, especially during turns or over bumps.

- Vehicle Pulling to One Side

- Misalignment caused by failing tie rod ends can cause the vehicle to drift.

- Vibrations in the Steering Wheel

- Damaged tie rod ends can lead to vibrations felt during driving, especially at high speeds.

Causes of Tie Rod End Wear

- Regular Use

- Continuous motion and stress during steering and suspension activities cause natural wear over time.

- Road Conditions

- Driving on rough, uneven roads or hitting potholes accelerates wear and tear.

- Lack of Maintenance

- Neglecting regular inspections and lubrication can lead to premature failure.

- Exposure to Elements

- Dirt, debris, and moisture can compromise the protective boot, leading to corrosion and degradation of the ball joint.

Maintenance and Care for Tie Rod Ends

- Regular Inspections

- Check for signs of wear, looseness, or damage during routine vehicle maintenance.

- Proper Lubrication

- Ensure the ball joint is adequately lubricated to minimize friction and extend its lifespan.

- Wheel Alignment

- Perform regular wheel alignments to maintain optimal geometry and prevent uneven stress on tie rod ends.

- Avoid Harsh Driving

- Minimize aggressive maneuvers, such as sudden turns or driving on poor road surfaces.

- Replace Protective Boots

- Ensure the rubber boots are intact to prevent contamination and preserve joint integrity.

Replacing Tie Rod Ends

Tools Needed

- Wrenches

- Tie rod end puller

- Torque wrench

- Replacement tie rod ends (R and L)

Step-by-Step Process

- Raise and Secure the Vehicle

- Use a jack and jack stands to lift the vehicle safely.

- Remove the Wheel

- Take off the wheel to access the tie rod end.

- Loosen the Lock Nut

- Loosen the lock nut securing the tie rod end to the inner tie rod.

- Detach the Tie Rod End

- Use a tie rod end puller to separate the tie rod end from the steering knuckle.

- Unscrew the Tie Rod End

- Count the number of turns required to remove the old tie rod end to ensure correct installation of the new one.

- Install the New Tie Rod End

- Screw the new tie rod end into place, matching the original orientation.

- Secure the Assembly

- Tighten the lock nut and reattach the tie rod end to the steering knuckle. Torque to the manufacturer’s specifications.

- Reassemble and Align

- Reinstall the wheel and ensure proper wheel alignment.

Cost of Replacement

The cost of replacing tie rod ends depends on the vehicle model, type of tie rod ends, and labor costs:

- Parts Cost: $20–$100 per tie rod end (OEM and aftermarket options).

- Labor Cost: $50–$150 depending on the complexity of the vehicle’s steering system.

Safety and Environmental Considerations

- Disposal of Old Parts

- Dispose of worn tie rod ends responsibly as they may contain materials harmful to the environment.

- Choose Certified Parts

- Use high-quality or OEM-certified replacements to ensure safety and reliability.

Conclusion

The tie rod end sub-assembly (R/L) is a vital component of a vehicle’s steering system, ensuring precise control, stability, and safety. Regular inspections, timely maintenance, and using high-quality replacements can extend the lifespan of tie rod ends and improve overall vehicle performance. Understanding their functions and importance enables better care and a safer driving experience.

Follow us on Facebook for more parts.