-8%

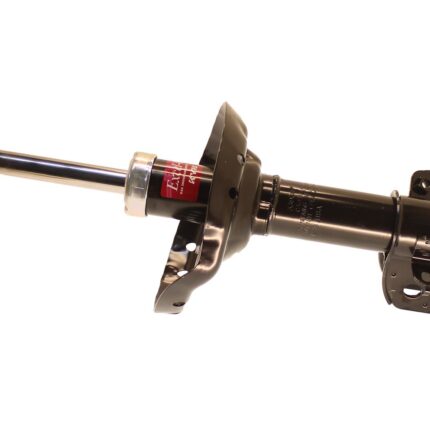

Get Subaru Impreza GP2 Rear Shock Absorber Assy 340096 in Kenya

In every mechanical system where movement meets momentum, there’s one key element responsible for balance, safety, and comfort—the Shock Absorber. Specifically, the Rear Shock Absorber Assembly plays a vital role in how a structure handles stress, absorbs energy, and delivers stability under pressure.

More than just a cushion for impacts, this advanced component is a precision-engineered system built to reduce vibrations, improve control, and deliver a smooth, predictable experience across diverse terrains and dynamic conditions. If consistency and durability matter, then the rear shock absorber assembly is where your confidence begins.

🌐 The Function Behind the Form

Let’s start at the core: what does a rear shock absorber assembly actually do? It’s far more than just a spring and a tube. It is a sophisticated combination of:

-

Hydraulic dampers

-

Multi-layer pistons

-

Reinforced mounting points

-

Robust seals and bushings

These components work in harmony to absorb kinetic energy, reduce unwanted motion, and control the vertical movement between the frame and the supporting structure. Whether during a sharp jolt or over prolonged undulating paths, the rear shock assembly ensures stability, control, and comfort through it all.

⚖️ Precision Damping for Balanced Performance

One of the biggest strengths of a high-quality rear shock absorber assembly is its ability to maintain uniform damping force. Designed with calibrated internal valving and high-grade hydraulic fluid, the assembly absorbs abrupt energy spikes without transferring them through the system 🌊🧊.

This translates to:

-

Minimized oscillations 🌀

-

Improved stability on uneven ground

-

Reduced wear on surrounding components

-

Enhanced operational efficiency over time

No matter the intensity of the terrain, the damping response remains controlled, linear, and predictable.

🔧 Built for Strength & Durability

Durability isn’t just an added benefit—it’s a necessity. The rear shock absorber assembly is often exposed to some of the most punishing conditions: dirt, dust, moisture, and repeated dynamic loads. That’s why it’s built with:

-

Heavy-duty metal alloys for structural strength

-

Corrosion-resistant coatings to fight rust and wear

-

Multi-sealed chambers to prevent fluid leaks and gas escape

-

Reinforced bushings for superior vibration isolation

These materials and design features combine to deliver a long-lasting, maintenance-friendly experience, especially in high-demand use cases 🌪️🛡️.

💨 Control Over Every Bump and Curve

A rear shock absorber assembly doesn’t just handle impact—it controls how that impact is transmitted and resolved. With each bump or dip, the piston inside the absorber moves through hydraulic fluid, converting kinetic energy into heat that dissipates harmlessly. The result? No bounce. No sway. Just seamless motion.

This leads to improved:

-

Traction and surface grip

-

Handling accuracy

-

Control during sudden stops or turns

-

Responsiveness across all operating conditions

This isn’t just comfort—it’s enhanced control that protects the whole system.

❄️ Performs in All Climates

From hot and dry to cold and icy, the rear shock absorber assembly is engineered to perform reliably in all environments. The multi-grade hydraulic oil used within is designed to maintain its viscosity across temperature changes, ensuring steady damping force, even in extreme climates ☀️❄️.

Cold-starts won’t stiffen it. Heat won’t thin it out. It’s made to handle real-world weather extremes without compromising on performance.

🔁 Easy Installation, Long-Term Value

Modern rear shock assemblies are engineered for straightforward installation, thanks to:

-

Pre-aligned mounting points

-

Precision-threaded studs and nuts

-

Universal-compatible design options

-

Pre-pressurized internals

This means less time on setup, reduced installation errors, and quicker returns to full operation 🧰🕒. Once installed, the self-contained design requires minimal maintenance, making it an ideal long-term solution for any setup focused on reliability and efficiency.

💬 Reduced Noise and Vibrations

Noise, Vibration, and Harshness (NVH) control is a major concern in performance applications. The rear shock absorber assembly features advanced rubber or polyurethane bushings, which serve to:

-

Absorb micro-vibrations

-

Minimize metal-on-metal contact

-

Reduce operating noise

-

Improve overall system feel

The result is a quieter, smoother, more controlled system response that feels refined and professional with every cycle 🔇🧘.

🎯 Application Versatility

Whether you’re navigating demanding terrain, operating under consistent load, or just requiring dependable damping over time, this shock absorber assembly adapts to the task. It’s built to serve:

-

Standard systems

-

Heavy-load applications

-

Performance-focused builds

-

Utility and recreational configurations

Versatility is built into the very design. With its responsive damping curve and durable construction, this is one component that meets diverse requirements with the same dependable results.

🧪 Tested to the Extreme

Every Rear Shock Absorber Assembly undergoes extensive quality testing, including:

-

Hydraulic pressure tolerance tests

-

Thermal resistance simulations

-

Endurance cycling across thousands of repetitions

-

Salt spray and corrosion trials

Only units that pass the highest standards make it into the field. That means what you install is not only functional—it’s proven under pressure 🧪✅.

🌿 Efficiency That Lasts

An efficient shock absorber isn’t just about comfort—it’s about protecting every part of the system. Reduced stress on joints, bushings, and structural parts leads to:

-

Fewer service calls

-

Lower operating fatigue

-

Reduced energy loss from unnecessary movement

-

Improved overall structural longevity

By controlling energy transfer, it reduces downstream strain—keeping systems in prime condition for longer 🛠️💚.

🚀 The Core of Confidence

From the first cycle to the thousandth, the Rear Shock Absorber Assembly delivers more than just damping. It provides confidence. Confidence that every motion will be controlled. Every impact managed. Every operation smoother than the last.

Engineered with precision. Crafted for durability. Trusted for performance.

Follow us on Facebook for more parts.