-4%

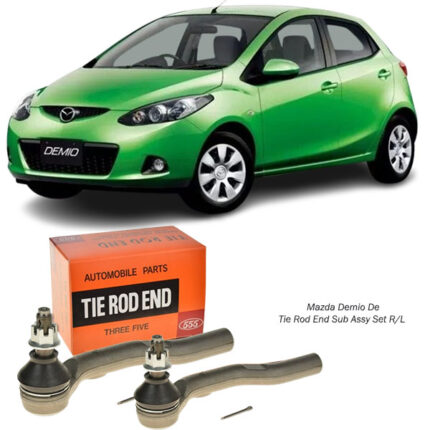

Get Mazda Demio DE Steering Rack End Sub-Assy SR1800 in Kenya

The steering rack end sub-assembly, commonly known as the inner tie rod, is a key component of a vehicle’s steering system. It plays an integral role in connecting the steering rack to the outer tie rod and, ultimately, the front wheels. This part ensures precise steering control and stability, making it indispensable for safe and responsive driving. In this comprehensive guide, we’ll cover its function, structure, benefits, common issues, maintenance tips, and replacement process.

What is a Steering Rack End Sub-Assembly?

The steering rack end sub-assembly consists of:

- Threaded Shaft: Connects the steering rack to the outer tie rod.

- Ball Joint: Allows smooth articulation and flexibility to accommodate suspension and steering movements.

- Protective Boot: Shields the inner tie rod from dirt, moisture, and contaminants.

This assembly serves as the intermediary between the steering rack, which translates the driver’s input into lateral motion, and the outer tie rods, which connect to the wheels.

How Does the Steering Rack End Sub-Assembly Work?

When the driver turns the steering wheel, the input is transmitted through the steering column to the steering rack. The steering rack moves laterally (side to side) based on the wheel’s direction. The rack end sub-assembly, which is attached to both the steering rack and the outer tie rod, transmits this movement to the wheels.

Key functions include:

- Translating Movement: It translates the lateral motion of the steering rack into wheel movement.

- Absorbing Flex: The ball joint absorbs suspension and steering flex, allowing the system to adjust for uneven road surfaces.

- Maintaining Alignment: Ensures the wheels remain aligned and stable during movement.

Functions of the Steering Rack End Sub-Assembly

- Steering Precision

The sub-assembly allows the vehicle to respond accurately to steering input, ensuring predictable handling. - Flexibility

The ball joint provides the necessary flexibility to accommodate road irregularities and suspension movement without compromising control. - Durability

By transmitting force from the steering rack while withstanding dynamic loads, the rack end sub-assembly enhances the longevity of the steering system. - Safety

A properly functioning rack end sub-assembly ensures the wheels turn as intended, minimizing the risk of accidents.

Benefits of a Steering Rack End Sub-Assembly

- Enhanced Handling

A robust rack end sub-assembly ensures the vehicle maintains stability and control, even at high speeds or on rough terrain. - Improved Steering Feedback

With a functional rack end sub-assembly, drivers experience precise and responsive steering feedback. - Reduced Tire Wear

Proper alignment facilitated by the sub-assembly prevents uneven tire wear, prolonging tire life. - Longer System Life

By absorbing road shocks and distributing loads efficiently, the component protects the steering rack and tie rods from premature wear. - Noise Reduction

A well-maintained rack end sub-assembly prevents clunking or rattling noises, ensuring a quieter ride.

Signs of a Worn Steering Rack End Sub-Assembly

- Steering Play

Excessive looseness or “play” in the steering wheel often indicates a worn rack end. - Clunking or Knocking Sounds

Noises during steering or when driving over bumps suggest wear or damage to the ball joint. - Uneven Tire Wear

A failing sub-assembly can cause misalignment, leading to uneven or rapid tire wear. - Steering Vibration

Vibration in the steering wheel while driving, especially at high speeds, may point to an issue with the rack end. - Difficulty Steering

Increased resistance or stiffness when turning the wheel could indicate damage to the component. - Vehicle Pulling

The vehicle may pull to one side if the rack end sub-assembly is compromised.

Causes of Steering Rack End Sub-Assembly Failure

- Wear and Tear

Prolonged use, especially under harsh driving conditions, leads to the degradation of the ball joint and threads. - Contaminant Exposure

Dirt, moisture, and debris can penetrate a damaged protective boot, accelerating wear. - Overloading

Excessive loads or hard impacts (e.g., hitting potholes or curbs) can damage the sub-assembly. - Poor Maintenance

Neglecting regular inspections and lubrication increases the likelihood of failure.

Maintenance Tips for Steering Rack End Sub-Assembly

- Regular Inspections

Inspect the sub-assembly during routine servicing for signs of wear, looseness, or damage. - Check Protective Boots

Ensure the rubber boots are intact and free from cracks or tears to prevent dirt ingress. - Monitor Steering Performance

Address any unusual noises, vibrations, or steering issues promptly to avoid further damage. - Wheel Alignment

Regular alignment checks reduce stress on the sub-assembly and prevent uneven wear. - Lubrication

Proper lubrication of the ball joint ensures smooth operation and reduces friction. - Replace in Pairs

When replacing one rack end, consider replacing the other to maintain balanced steering performance.

Replacement of Steering Rack End Sub-Assembly

Replacing a rack end sub-assembly requires technical expertise and the right tools. Here’s an outline of the process:

- Lift the Vehicle

Use a jack to lift the front of the vehicle and secure it with jack stands. - Remove the Wheel

Detach the wheel on the side of the rack end being replaced to access the suspension and steering components. - Disconnect the Outer Tie Rod

Loosen and remove the nut securing the outer tie rod to the steering knuckle. Use a tie rod puller to separate it. - Detach the Rack End Sub-Assembly

Remove the clamps securing the protective boot. Unscrew the rack end from the steering rack using an inner tie rod tool. - Inspect Components

Check the outer tie rod, protective boot, and steering rack for damage. Replace if necessary. - Install the New Rack End

Screw the new rack end onto the steering rack, ensuring it is securely fastened. Reattach the protective boot with clamps. - Reconnect the Outer Tie Rod

Reinstall the outer tie rod and secure it to the steering knuckle. - Align the Wheels

Perform a wheel alignment to ensure proper handling and prevent uneven tire wear. - Test Drive

Take the vehicle for a test drive to verify smooth and responsive steering.

When to Replace the Steering Rack End Sub-Assembly

Replacement intervals depend on driving conditions and maintenance. Typically, it lasts between 50,000 and 100,000 miles, but you should replace it if:

- There are signs of excessive wear or damage.

- The steering feels loose or unresponsive.

- The protective boot is torn, exposing the ball joint to contaminants.

Cost of Replacement

The cost of replacing a steering rack end sub-assembly varies depending on the vehicle make, model, and labor charges. While the part itself is relatively affordable, professional installation ensures safety and precision.

Conclusion

The steering rack end sub-assembly is vital for maintaining precise and safe steering. Regular inspection, timely maintenance, and prompt replacement of worn components can ensure your vehicle handles smoothly and predictably. By understanding its function and importance, drivers can enjoy enhanced safety, comfort, and performance on the road.

Follow us on Facebook for more parts.