-17%

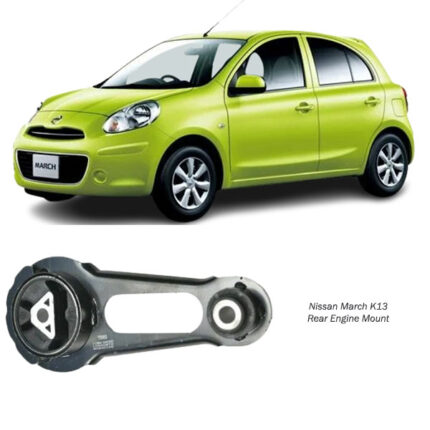

Get Nissan March K13 JPN LH Engine Mount 11220-1HC0C in Kenya

The left-hand (LH) engine mount, commonly called the engine mount or motor mount, is a crucial component in a vehicle’s drivetrain, specifically designed to secure the engine to the vehicle’s chassis. This essential part helps isolate vibrations, absorbs shocks, and ensures the engine remains stable under various driving conditions. In this detailed guide, we will explore the LH engine mount’s functions, materials, signs of wear, maintenance, and installation considerations.

1. Purpose and Function of the LH Engine Mount

The LH engine mount serves several key functions in the vehicle:

- Stabilizing the Engine: The mount secures the engine in the vehicle’s engine bay, preventing it from moving excessively during operation. A secure engine improves the vehicle’s handling, performance, and safety.

- Vibration Isolation: By absorbing engine vibrations, the mount prevents them from transferring into the cabin, providing a smoother and quieter ride for passengers.

- Shock Absorption: When the vehicle is driven over rough terrain, speed bumps, or during sudden acceleration and deceleration, the engine mount absorbs shocks, reducing stress on the engine and surrounding components.

- Alignment Maintenance: It maintains the engine in the correct position, ensuring that various connected systems such as the transmission, driveshaft, and exhaust are properly aligned. This alignment is essential for overall vehicle performance and smooth power transfer.

Since the LH engine mount is located on the left side (driver’s side for left-hand drive vehicles), it often endures more stress due to the weight distribution of the engine. This makes it especially important in maintaining engine stability.

2. Types of Engine Mounts and Materials

Engine mounts come in various types, each designed to suit different engine configurations and performance requirements:

a) Rubber Engine Mounts

Rubber mounts are the most common type found in standard vehicles. They are designed with a metal frame and rubber cushion, allowing for effective vibration damping. The rubber provides a balance between comfort and durability but can deteriorate over time due to heat and chemical exposure.

b) Hydraulic Engine Mounts

Hydraulic mounts contain a fluid-filled chamber within a rubber or elastomeric housing. They are typically used in higher-end or luxury vehicles, as the fluid enhances vibration isolation. Hydraulic mounts are especially effective in reducing vibrations at idle but may require more frequent maintenance compared to solid rubber mounts.

c) Polyurethane Engine Mounts

For performance vehicles, polyurethane mounts are sometimes used. These mounts are stiffer than rubber, offering better handling and less flex under high-torque situations. However, they transmit more vibrations into the cabin, making them less suitable for comfort-focused vehicles.

3. Signs of Wear and Failure in LH Engine Mounts

Engine mounts endure constant stress and exposure to heat, which means they can eventually wear out. Some common signs of a worn or failing LH engine mount include:

a) Increased Vibrations

When the LH engine mount starts to fail, it may not isolate vibrations effectively, resulting in noticeable shaking in the cabin, particularly during idling or acceleration.

b) Clunking or Banging Noises

A worn mount may allow excessive engine movement, causing the engine to make clunking or banging noises as it contacts other components in the engine bay.

c) Misalignment or Leaning Engine

If the mount has degraded significantly, the engine may sit misaligned or appear to lean towards one side. This can cause problems with connected systems like the transmission and exhaust.

d) Visible Cracks or Tears in the Mount

Inspecting the engine mount may reveal visible cracks or tears, particularly in the rubber. This is a clear sign that the mount needs replacement.

e) Engine Movement During Shifting

Excessive engine movement or shifting when accelerating, decelerating, or changing gears indicates that the mount is no longer providing adequate stability.

4. Maintenance of LH Engine Mounts

Maintaining the LH engine mount can help prolong its life and ensure optimal engine stability. Here are some maintenance tips:

a) Regular Inspections

Regularly inspecting the LH engine mount for signs of wear or damage can help catch problems early. Look for visible cracks, tears, or sagging in the rubber or elastomer.

b) Avoiding Aggressive Driving

Aggressive driving, such as rapid acceleration, hard braking, or frequent off-roading, can put additional stress on the engine mounts. Adopting smoother driving habits can help reduce wear.

c) Preventing Exposure to Chemicals

Engine mounts, particularly rubber mounts, can degrade if exposed to oil, coolant, or other chemicals. Ensure there are no fluid leaks in the engine bay that could damage the mount.

d) Replace When Needed

Engine mounts are generally designed to last between 5 to 10 years, depending on the driving conditions and vehicle type. If any symptoms of wear or failure appear, replace the mount promptly to prevent further damage.

5. Replacement of the LH Engine Mount

Replacing an LH engine mount can restore vehicle stability, reduce vibrations, and improve overall performance. Here’s a step-by-step guide to the replacement process:

a) Tools Required

- Socket set and wrenches

- Jack and jack stands

- Pry bar (if needed)

- Torque wrench

b) Replacement Steps

- Lift the Vehicle: Use a jack to lift the vehicle and secure it with jack stands. Make sure the vehicle is stable before proceeding.

- Support the Engine: Before removing the mount, use a second jack to support the engine. Place a block of wood between the jack and the oil pan to avoid damage.

- Locate the LH Engine Mount: The LH engine mount is typically located on the left side of the engine bay. Consult the vehicle’s manual for the exact location and configuration.

- Remove the Old Mount: Use a socket set or wrench to remove the bolts securing the mount to the engine and chassis. If necessary, use a pry bar to carefully remove the mount from its housing.

- Install the New Mount: Position the new LH engine mount in place, aligning it with the bolt holes. Secure the mount by tightening the bolts to the manufacturer’s specified torque settings.

- Lower the Engine: Once the new mount is secured, gently lower the engine back into position and remove the supporting jack.

- Test Drive the Vehicle: After installation, take the vehicle for a test drive to ensure the mount is functioning properly. Check for any abnormal vibrations or noises.

6. Importance of Quality in LH Engine Mounts

The quality of the engine mount can significantly affect vehicle performance, comfort, and safety. Investing in a high-quality mount ensures:

- Durability: Premium mounts are built to withstand extreme conditions, providing longer service life and reducing the frequency of replacements.

- Enhanced Comfort: High-quality mounts offer better vibration damping, contributing to a quieter and more comfortable ride.

- Improved Performance: A durable and well-designed engine mount helps maintain alignment, improving handling and responsiveness.

OEM (Original Equipment Manufacturer) mounts are generally recommended for most vehicles, as they are specifically designed for the make and model, ensuring compatibility and performance.

7. Conclusion

The LH engine mount plays a vital role in securing the engine, isolating vibrations, and absorbing shocks. It ensures that the engine remains stable under various driving conditions, contributing to a smoother and safer driving experience. Recognizing the signs of wear and conducting regular maintenance can extend the life of the LH engine mount and prevent issues that may affect vehicle performance. When it comes time to replace the mount, quality and precision in installation are paramount. By understanding the function and importance of the LH engine mount, vehicle owners can prioritize its maintenance and replacement, ensuring their vehicle remains reliable, comfortable, and efficient on the road.

Follow us on Facebook for more parts.