-5%

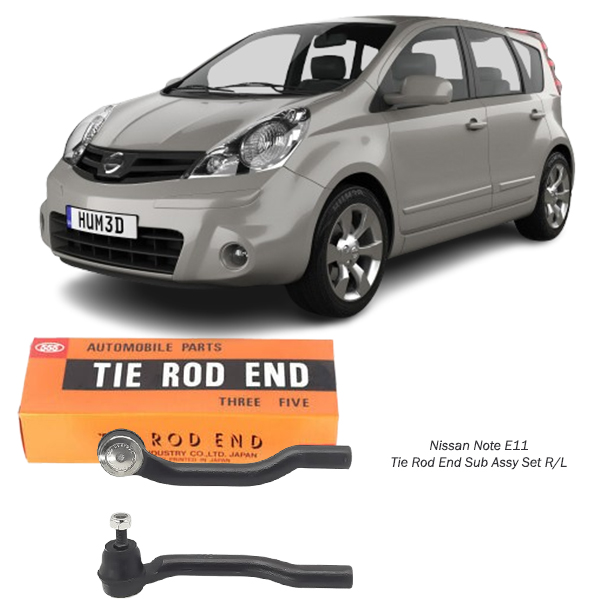

Get Nissan Note E11 Tie Rod End Sub Assy Set R/L SE4951 in Kenya

The Tie Rod End Sub-Assembly Set is a crucial component within a vehicle’s steering system. Tie rod ends play a significant role in connecting the steering system to the wheels, allowing the driver to control the direction of the vehicle accurately. This set, often comprising both inner and outer tie rod ends, works as part of the link between the steering rack and the steering knuckle on each wheel. Due to their essential role in steering, handling, and safety, tie rod ends require regular inspection and maintenance.

This comprehensive guide will delve into the construction, function, maintenance, benefits, and signs of wear for tie rod ends, helping drivers and vehicle enthusiasts understand their importance in a car’s steering and suspension system.

1. What is a Tie Rod End Sub-Assembly Set?

The Tie Rod End Sub-Assembly Set consists of inner and outer tie rod ends, which are part of the vehicle’s steering mechanism. They connect the steering rack or steering gear to the wheel hub assembly, allowing the driver to steer the vehicle. When the steering wheel is turned, the tie rods transmit this motion to the wheels, enabling the vehicle to change direction.

Tie rod ends are located at each side of the vehicle’s front suspension and often in the rear suspension of certain vehicles. Each tie rod end is equipped with a ball joint to provide flexibility, allowing the wheel to pivot as the suspension moves over different road surfaces. The tie rod end assembly is built to handle both vertical movement from the suspension and rotational movement from the steering.

2. Components of a Tie Rod End Sub-Assembly Set

A typical tie rod end sub-assembly set contains the following components:

a. Inner Tie Rod

The inner tie rod connects directly to the steering rack or steering gear. It has a threaded end that allows adjustment, enabling precise alignment of the wheels.

b. Outer Tie Rod

The outer tie rod connects to the inner tie rod and is attached to the steering knuckle, which connects to the wheel hub. The outer tie rod transfers motion from the inner tie rod to the wheels.

c. Ball Joint

Both inner and outer tie rod ends are equipped with ball joints. These ball-and-socket joints allow for pivoting and rotational motion, making it possible for the wheels to turn while accommodating movement in the suspension.

d. Dust Boot

The ball joints on the tie rod ends are protected by a dust boot, a rubber or synthetic cover that keeps dirt, debris, and moisture away from the joint. This prevents wear and tear on the ball joint.

e. Lock Nut

Tie rod ends have lock nuts to keep the assembly secure and prevent loosening. They help maintain the adjustment made during wheel alignment.

3. Functions of the Tie Rod End Sub-Assembly Set

The tie rod end sub-assembly set is integral to the steering and suspension system and performs several key functions:

a. Transmitting Steering Input

Tie rod ends transmit the motion from the steering rack to the wheels, allowing the vehicle to change direction in response to the driver’s input.

b. Maintaining Alignment

Tie rod ends help maintain proper wheel alignment, ensuring the wheels point in the desired direction. Proper alignment is crucial for vehicle stability, tire wear, and handling.

c. Absorbing Suspension Movement

The ball joints within the tie rod ends absorb suspension movement, allowing the wheels to pivot while moving vertically in response to uneven road surfaces. This flexibility contributes to a smooth and stable driving experience.

d. Providing Vehicle Stability

Tie rod ends, by keeping the wheels aligned and connected to the steering system, contribute to vehicle stability, especially when cornering or driving on rough roads.

4. Types of Tie Rod Ends

Tie rod ends can vary based on vehicle design and steering system requirements. Here are the common types:

a. Rack-and-Pinion Tie Rod Ends

Found in most modern vehicles with rack-and-pinion steering, these tie rod ends consist of an inner and outer tie rod. They connect the steering rack directly to the wheels.

b. Parallelogram Steering Linkage Tie Rod Ends

Used in vehicles with parallelogram-type steering (often in trucks or older vehicles), these tie rod ends are connected in pairs and may also include an idler arm to support the steering linkage.

c. Adjustable Tie Rod Ends

Adjustable tie rod ends allow for more precise wheel alignment, making them common in performance or modified vehicles. They feature threads that can be adjusted to change the length of the tie rod for improved handling or alignment.

5. Signs of a Worn Tie Rod End

Recognizing signs of wear in a tie rod end can prevent steering and handling issues. Some common symptoms of a failing tie rod end include:

a. Vibrations and Shaking

A worn tie rod end can cause vibrations in the steering wheel, especially at higher speeds. This vibration often occurs when the ball joint or inner assembly becomes loose.

b. Clunking or Knocking Noises

Damaged or worn tie rod ends can produce a clunking or knocking noise, particularly when turning the steering wheel or driving over bumps. This noise often results from a loose or damaged ball joint.

c. Uneven or Excessive Tire Wear

When tie rod ends wear out, they may cause misalignment, leading to uneven tire wear. This issue can reduce tire lifespan and lead to costly replacements if not addressed.

d. Poor Steering Response

If a tie rod end is loose or damaged, the vehicle may experience a delayed or less responsive steering response, making it harder to control the car accurately.

e. Pulling to One Side

A failing tie rod end can cause the vehicle to pull to one side, as the wheels are not aligned correctly.

6. Maintenance and Replacement of Tie Rod Ends

Regular inspection and maintenance of tie rod ends are essential to keep the steering system in good working condition. Here’s what maintenance involves:

a. Inspection

Regular inspections are recommended during routine maintenance or tire rotations. Mechanics check for signs of wear, such as torn dust boots, loose ball joints, or corrosion.

b. Lubrication

Some tie rod ends are sealed and do not require lubrication, while others may have grease fittings that need periodic lubrication to ensure smooth operation.

c. Replacement of Worn Parts

When a tie rod end shows significant wear or damage, it’s important to replace it promptly. Neglecting to replace a worn tie rod end can lead to steering problems, misalignment, and accelerated tire wear.

d. Wheel Alignment

After replacing a tie rod end, a wheel alignment is necessary to ensure proper steering and tire wear. Misalignment can impact vehicle stability and handling.

7. Benefits of a Functional Tie Rod End Sub-Assembly

A properly functioning tie rod end assembly offers multiple benefits, including:

a. Improved Steering Accuracy

Tie rod ends provide accurate and responsive steering, enabling the driver to control the vehicle’s direction effectively.

b. Enhanced Safety

Good quality tie rod ends contribute to vehicle stability and handling, improving safety during turns, sudden maneuvers, and emergency situations.

c. Reduced Tire Wear

When tie rod ends keep the wheels aligned, tires wear evenly, extending their lifespan and saving on replacement costs.

d. Better Ride Comfort

Smooth, responsive steering and minimized vibrations lead to a more comfortable and enjoyable driving experience.

e. Preservation of Suspension Components

Healthy tie rod ends reduce strain on the rest of the suspension system, including control arms, ball joints, and bushings, leading to longer-lasting components.

8. Causes of Tie Rod End Wear

Tie rod ends are subject to wear due to several factors:

a. Road Conditions

Driving on rough roads, over potholes, or on uneven surfaces can accelerate tie rod end wear due to increased stress on the ball joints and bushings.

b. Environmental Exposure

Tie rod ends are exposed to water, salt, dirt, and debris, which can cause corrosion and degrade the dust boots, allowing contaminants to damage the ball joints.

c. High Mileage

With time and regular use, tie rod ends naturally wear out, especially in high-mileage vehicles.

d. Poor Maintenance

Neglecting routine inspections, alignment, or lubrication can accelerate wear and lead to premature failure of tie rod ends.

Conclusion

The Tie Rod End Sub-Assembly Set is an essential part of a vehicle’s steering and suspension system, responsible for translating the driver’s input into controlled wheel movement. Regular maintenance and timely replacement of worn tie rod ends ensure smooth, responsive steering and a safer, more comfortable driving experience. Understanding the importance of tie rod ends, recognizing signs of wear, and conducting regular inspections can help drivers keep their vehicles performing optimally.

Follow us on Facebook for more parts.