-12%

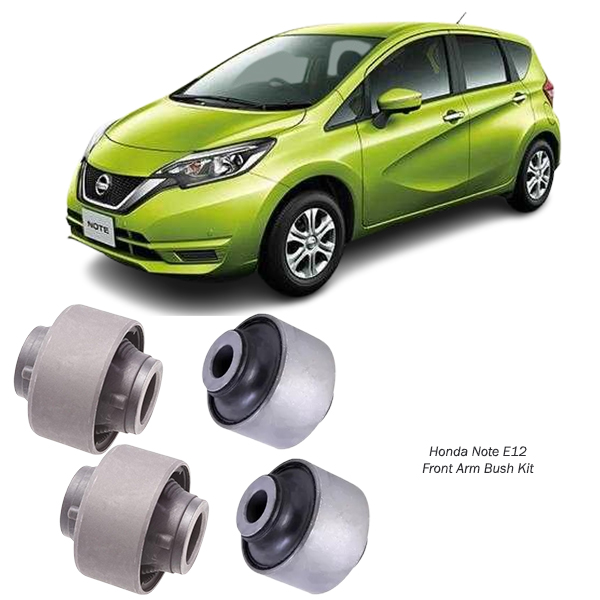

Get Nissan Note E12 Front Arm Bush Kit 54560-1HJ0A / 54570-1HJ0A in Kenya

The front arm bush kit is an essential part of a vehicle’s suspension system. Designed to provide flexibility and reduce vibrations, these bushings are placed within the front control arms, connecting them to the chassis and other suspension components. This guide explores the structure, functions, types, benefits, maintenance, and signs of wear of front arm bushes, alongside insights into their replacement and overall importance.

What Is a Front Arm Bush Kit?

The front arm bush kit typically includes multiple bushings made of durable materials like rubber or polyurethane. These bushings are fitted into the front suspension control arms and allow controlled movement, absorbing road shocks and vibrations.

Functions of the Front Arm Bush Kit

- Shock Absorption

The bushings act as cushions, absorbing road shocks and reducing the impact felt inside the cabin. - Noise and Vibration Dampening

By isolating vibrations between the control arm and the chassis, the bushings reduce noise for a smoother and quieter ride. - Enhanced Suspension Movement

The bushings allow the control arms to pivot smoothly, enabling better wheel movement and suspension articulation. - Improved Steering Stability

Properly functioning bushings ensure the alignment of suspension components, enhancing steering precision and vehicle stability. - Protection for Suspension Components

By reducing stress and wear on metal parts, bushings prolong the lifespan of suspension components like control arms and ball joints.

Construction of Front Arm Bushings

The front arm bushings are meticulously designed to endure the rigors of driving. Their structure includes:

- Outer Metal Shell

Provides structural integrity and connects the bushing to the control arm. - Inner Metal Sleeve

Houses the bolt that secures the bushing to the chassis or suspension mount. - Elastic Core

Typically made from rubber or polyurethane, this core absorbs shocks and allows controlled movement. - Lubricants or Coatings

Some bushings are pre-lubricated or coated to reduce friction and wear.

Types of Front Arm Bushings

- Rubber Bushings

- Common in passenger vehicles.

- Provide excellent vibration damping.

- Affordable but prone to wear over time.

- Polyurethane Bushings

- More durable and resistant to wear than rubber.

- Often used in performance or off-road vehicles.

- May transmit more vibrations than rubber.

- Hydraulic Bushings

- Feature fluid-filled chambers for superior damping.

- Common in high-end or luxury vehicles.

- Solid Bushings

- Designed for racing or heavy-duty applications.

- Offer precise control but lack vibration isolation.

Benefits of a Front Arm Bush Kit

- Improved Ride Comfort

High-quality bushings enhance ride smoothness by isolating road shocks and vibrations. - Increased Component Longevity

By reducing friction and stress, bushings protect suspension components from premature wear. - Better Steering Control

Properly functioning bushings ensure accurate steering responses and improved vehicle handling. - Reduced Maintenance Costs

Durable bushings lower the frequency of suspension repairs, saving on long-term costs. - Enhanced Safety

A stable suspension system contributes to overall vehicle safety, particularly during high-speed maneuvers or sudden stops.

Signs of Worn Front Arm Bushings

- Unusual Noises

Clunking or creaking sounds from the suspension, especially when turning or driving over bumps, indicate worn bushings. - Excessive Vibration

Increased vibrations in the steering wheel or cabin may signal that the bushings are no longer effective. - Uneven Tire Wear

Misaligned suspension components caused by worn bushings lead to irregular tire wear patterns. - Poor Handling

Loose or worn bushings can make the vehicle feel unstable, particularly during cornering. - Visual Damage

Cracks, tears, or deformations in the bushings are visible signs of wear.

Causes of Front Arm Bushing Wear

- Aging

Over time, rubber bushings degrade due to exposure to heat, moisture, and road contaminants. - Driving Conditions

Rough roads, potholes, and off-road terrain accelerate bushing wear. - High Temperatures

Prolonged exposure to high temperatures weakens the bushing material, reducing its elasticity. - Contaminants

Oil, grease, and road salt can degrade bushings, especially rubber ones. - Excessive Load

Carrying heavy loads or aggressive driving can increase stress on the bushings.

Maintenance of Front Arm Bushings

- Regular Inspections

Periodically check the bushings for signs of wear or damage, especially during routine suspension maintenance. - Lubrication

Use appropriate lubricants for bushings that require it to reduce friction and extend their lifespan. - Alignment Checks

Ensure proper wheel alignment to minimize stress on the bushings. - Avoid Harsh Conditions

Drive cautiously on rough roads and avoid overloading the vehicle. - Timely Replacement

Replace worn bushings promptly to prevent damage to other suspension components.

Replacement of Front Arm Bushings

Tools and Preparation

- Hydraulic press or bushing removal tool.

- Socket set and wrenches.

- Jack stands and a floor jack.

- Replacement bushings.

Steps for Replacement

- Lift the Vehicle

Secure the vehicle on jack stands and remove the front wheels. - Access the Control Arm

Remove components obstructing access, such as sway bars or other suspension parts. - Remove the Control Arm

Unbolt the control arm and take it out of the suspension assembly. - Extract the Old Bushings

Use a hydraulic press or specialized tools to push out the worn bushings. - Install New Bushings

Align the new bushings correctly and press them into place. - Reassemble the Suspension

Reinstall the control arm and any removed components, then tighten bolts to the manufacturer’s torque specifications. - Test Drive

After reassembly, test the vehicle for improved handling and reduced noise.

Common Mistakes During Replacement

- Improper Alignment

Misaligned bushings can lead to uneven wear and poor suspension performance. - Using Inferior Quality Bushings

Low-quality bushings may fail prematurely, causing repeated repairs. - Over-Tightening

Over-tightened bolts can compress the bushings, reducing their effectiveness. - Skipping Related Components

Neglecting to inspect other suspension parts may leave underlying issues unresolved.

Why Invest in a Quality Front Arm Bush Kit?

- Durability

High-quality bushings last longer and withstand harsh conditions better. - Performance

Superior materials ensure optimal suspension performance and handling. - Value for Money

Though initially costlier, premium bushings reduce long-term maintenance expenses.

Conclusion

The front arm bush kit is vital for ensuring a smooth, stable, and safe driving experience. By understanding its functions, benefits, and signs of wear, vehicle owners can better maintain their suspension systems. Regular inspections, timely replacements, and the use of high-quality bushings ensure the longevity of the suspension system and enhance overall vehicle performance.

Follow us on Facebook for more parts.