Description

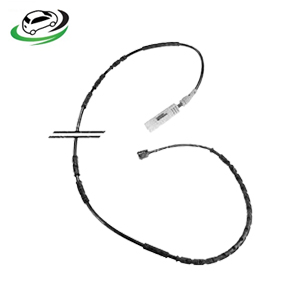

Get Audi TT MKI FWD 180HP Rear Oxygen Sensor 06A906262AJ in Kenya

The oxygen sensor, commonly known as the O2 sensor, is a crucial component in modern automotive engines. It plays a vital role in maintaining the optimal air-fuel mixture, thereby improving engine performance, fuel efficiency, and reducing emissions. This guide will delve into the oxygen sensor’s function, types, benefits, signs of failure, diagnostics, and maintenance in detail.

Function of the Oxygen Sensor

The oxygen sensor measures the amount of oxygen present in the exhaust gases as they exit the engine. This data is sent to the engine control unit (ECU), which uses the information to adjust the air-fuel mixture entering the engine. The goal is to achieve the optimal ratio, typically around 14.7:1 (air to fuel), known as the stoichiometric ratio.

- Air-Fuel Ratio Monitoring:

- Stoichiometric Ratio: The sensor helps maintain this ratio, which ensures complete combustion of the fuel. Too much air (lean mixture) or too little air (rich mixture) can lead to performance issues and increased emissions.

- Real-Time Adjustments: By constantly monitoring the exhaust gases, the oxygen sensor allows the ECU to make real-time adjustments to the fuel injection system, optimizing engine performance.

- Emission Control:

- Catalytic Converter Efficiency: The sensor also ensures the catalytic converter operates efficiently by maintaining the right air-fuel mixture. A well-functioning oxygen sensor helps the catalytic converter reduce harmful emissions such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

- Closed-Loop Operation: The sensor enables the ECU to operate in a closed-loop mode, where the air-fuel mixture is continuously adjusted for optimal combustion and minimal emissions.

- Fuel Efficiency:

- Fuel Economy: By maintaining the correct air-fuel ratio, the oxygen sensor ensures that the engine uses fuel efficiently. This helps in maximizing miles per gallon (MPG) and reducing fuel costs.

- Adaptive Learning: Modern ECUs use data from the oxygen sensor to adapt to changes in driving conditions, engine load, and other variables, further improving fuel efficiency.

Types of Oxygen Sensors

There are several types of oxygen sensors, each with its own design and application:

- Zirconia Oxygen Sensors:

- Construction: The most common type, zirconia sensors, use a ceramic element coated with a layer of zirconium dioxide. This element becomes electrically conductive at high temperatures, generating a voltage signal proportional to the oxygen level in the exhaust gas.

- Heated vs. Unheated: Zirconia sensors can be heated or unheated. Heated oxygen sensors (HO2S) have an internal heating element that allows them to reach operating temperature quickly, providing accurate readings shortly after engine start.

- Titania Oxygen Sensors:

- Construction: Titania sensors use titanium dioxide as the sensing element. Unlike zirconia sensors, they do not generate their own voltage but change resistance based on the oxygen level in the exhaust.

- Application: Titania sensors are less common but are used in some vehicles, particularly in specific engine management systems.

- Wideband Oxygen Sensors:

- Functionality: Wideband sensors, also known as air-fuel ratio (AFR) sensors, provide a more precise measurement of the air-fuel mixture. They can detect a broader range of air-fuel ratios, allowing for more accurate control of the mixture.

- Modern Use: These sensors are commonly used in modern vehicles with advanced fuel management systems, as they allow for finer control over the combustion process, improving performance and emissions.

Benefits of a Properly Functioning Oxygen Sensor

A well-functioning oxygen sensor offers several benefits:

- Optimized Engine Performance:

- Smooth Operation: By ensuring the correct air-fuel ratio, the sensor helps the engine run smoothly, with consistent power delivery and reduced engine knocking or hesitation.

- Enhanced Power: An optimal air-fuel mixture maximizes the power output of the engine, ensuring better acceleration and overall performance.

- Improved Fuel Efficiency:

- Reduced Fuel Consumption: Accurate air-fuel ratio control leads to efficient fuel use, helping drivers save on fuel costs.

- Less Frequent Refueling: With better fuel economy, drivers can go longer between refueling stops.

- Lower Emissions:

- Environmental Benefits: By helping the catalytic converter reduce harmful emissions, the oxygen sensor contributes to a cleaner environment.

- Compliance with Regulations: A properly functioning sensor ensures that the vehicle meets emission standards, which is important for passing vehicle inspections and avoiding fines.

- Extended Engine Life:

- Prevention of Engine Damage: A correct air-fuel mixture prevents conditions that can lead to engine damage, such as overheating or excessive carbon buildup.

- Reduced Wear and Tear: By optimizing combustion, the sensor helps reduce wear on engine components, potentially extending the engine’s lifespan.

Symptoms of a Failing Oxygen Sensor

A failing oxygen sensor can lead to several engine performance issues:

- Check Engine Light (CEL) Illumination:

- Trigger: A faulty oxygen sensor will often trigger the check engine light. The ECU detects that the sensor is not providing accurate data and logs a trouble code.

- Diagnostic Codes: Common codes related to oxygen sensor failure include P0130 (O2 Sensor Circuit Malfunction) and P0420 (Catalyst System Efficiency Below Threshold).

- Poor Fuel Economy:

- Increased Fuel Consumption: A failing sensor may cause the ECU to deliver too much or too little fuel, leading to poor fuel efficiency and increased fuel costs.

- Frequent Refueling: Drivers may notice that they need to refuel more often than usual.

- Rough Engine Idle and Misfires:

- Engine Misfires: A faulty sensor can cause incorrect air-fuel mixture adjustments, leading to engine misfires, especially at idle or low speeds.

- Rough Idle: The engine may run unevenly or vibrate excessively when idling.

- Failed Emissions Test:

- Increased Emissions: If the sensor is not functioning properly, the vehicle may produce higher levels of pollutants, leading to a failed emissions test.

- Need for Replacement: A failed sensor must be replaced to pass the test and meet environmental regulations.

- Performance Issues:

- Lack of Power: The engine may feel sluggish or underpowered, particularly during acceleration.

- Hesitation: There may be noticeable hesitation when pressing the accelerator, especially when the engine is under load.

Diagnosing and Replacing a Faulty Oxygen Sensor

Diagnosing a faulty oxygen sensor typically involves the following steps:

- Diagnostic Scan:

- OBD-II Scanner: Use an OBD-II scanner to read the trouble codes stored in the ECU. Codes related to oxygen sensor issues will help pinpoint the problem.

- Code Analysis: Analyze the codes to determine if the issue is with the sensor itself or another related component, such as the wiring or catalytic converter.

- Visual Inspection:

- Check Wiring: Inspect the sensor’s wiring for damage, corrosion, or loose connections, which could affect the sensor’s performance.

- Sensor Condition: Visually examine the sensor for signs of wear, contamination, or physical damage.

- Sensor Testing:

- Multimeter Test: Use a multimeter to check the sensor’s voltage output and compare it to the manufacturer’s specifications. An abnormal reading may indicate a faulty sensor.

- Oscilloscope Test: An oscilloscope can be used for a more detailed analysis of the sensor’s output waveform, showing if it is responding correctly to changes in the exhaust gas composition.

- Replacement:

- Remove the Old Sensor: Once diagnosed as faulty, the old sensor can be removed using a sensor socket or wrench.

- Install the New Sensor: Install the new sensor, ensuring it is properly connected to the wiring harness and tightened to the correct torque specification.

Maintenance of the Oxygen Sensor

Maintaining the oxygen sensor involves regular checks and proper care:

- Regular Inspections:

- Scheduled Maintenance: Include the oxygen sensor in your vehicle’s routine maintenance schedule, especially if you notice any symptoms of failure.

- Cleanliness: Keep the sensor and its surrounding area clean to prevent contamination that could interfere with its operation.

- Prompt Attention to CEL:

- Immediate Diagnosis: If the check engine light comes on and diagnostic codes point to the oxygen sensor, address the issue promptly to avoid further engine damage.

- Replacement Interval:

- Manufacturer’s Recommendations: Follow the vehicle manufacturer’s recommendations for oxygen sensor replacement intervals, typically every 60,000 to 100,000 miles, depending on the sensor type and vehicle.

- Use Quality Parts:

- OEM Sensors: Use original equipment manufacturer (OEM) sensors or high-quality aftermarket parts to ensure reliable performance and compatibility with your vehicle.

Follow us on Facebook for more parts.