-20%

Get Seal Nozzle Holder Set Of Four 2368130010

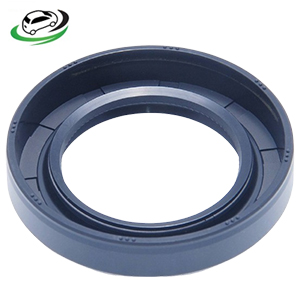

The seal nozzle holder, also known as the nozzle holder seal or injector seal, is a small yet crucial component in a diesel engine’s fuel injection system. Its primary function is to seal the connection between the fuel injector nozzle holder and the cylinder head, preventing fuel leaks and ensuring proper fuel delivery to the engine cylinders. This article delves into the function, importance, materials, common issues, replacement process, and maintenance of the seal nozzle holder.

Function and Importance

The seal nozzle holder plays several critical roles within the fuel injection system:

- Sealing: Its primary function is to create a tight seal between the injector nozzle holder and the cylinder head. This prevents fuel from leaking out of the system, which could lead to fuel inefficiency, engine performance issues, and potential fire hazards.

- Pressure Management: The seal helps to maintain the high pressure required for efficient fuel atomization and combustion inside the engine cylinders. A proper seal ensures that the fuel is delivered accurately and at the right pressure.

- Heat and Chemical Resistance: The seal must withstand the high temperatures and chemical exposure within the engine compartment without deteriorating or deforming, ensuring long-term reliability.

Materials

Seal nozzle holders are typically made from materials that offer resilience against heat, pressure, and chemical exposure commonly found in the engine environment:

- Viton: A type of synthetic rubber known for its excellent heat resistance, chemical resistance, and durability. Viton seals are commonly used in diesel engines due to their ability to withstand high temperatures and exposure to diesel fuel.

- Nitrile (Buna-N): Another type of synthetic rubber that provides good resistance to oils, fuels, and chemicals. Nitrile seals are cost-effective and widely used in automotive applications.

- Fluorosilicone: Combines the properties of silicone and fluorocarbon elastomers, offering good resistance to fuel and oil, as well as high and low-temperature extremes.

- Polyurethane: Known for its high strength and abrasion resistance, polyurethane seals are suitable for applications where durability and wear resistance are critical.

Common Issues

Over time, seal nozzle holders can experience wear or damage, leading to several potential issues:

- Fuel Leaks: A deteriorated or damaged seal can cause fuel to leak from the injector nozzle holder. This may manifest as visible fuel stains around the injector or a noticeable fuel odor.

- Poor Engine Performance: Fuel leaks can disrupt the precise fuel delivery required for optimal engine combustion, leading to rough idling, decreased fuel efficiency, and reduced engine power.

- Hard Starting or No Start Condition: Severe leaks or complete seal failure can prevent the engine from starting altogether, as the fuel delivery to the cylinders may be compromised.

- Engine Misfires: Inconsistent fuel delivery due to seal issues can cause engine misfires, where cylinders fail to ignite fuel properly. This results in rough running, loss of power, and potential damage to engine components.

Replacement and Maintenance

Replacing the seal nozzle holder is a critical maintenance task that should be performed as part of routine diesel engine maintenance or when symptoms of seal wear or leakage are detected:

- Diagnostic Inspection: If fuel leakage or performance issues are suspected, conduct a thorough inspection of the fuel injectors and nozzle holders. This may involve visual inspection for fuel stains, checking for fuel odors, or performing a pressure test to pinpoint leaks.

- Preparation: Ensure the engine is cool and disconnect the battery to prevent accidental starts. Gather the necessary tools and replacement seals.

- Access and Removal: Access the injector nozzle holders by removing any components blocking their access, such as air intake ducts or engine covers.

- Seal Replacement: Carefully remove the old seals using appropriate tools, taking care not to damage the injector or nozzle holder. Clean the seating area thoroughly to ensure a proper seal for the new seals.

- Installation: Install the new seals onto the injector nozzle holders, ensuring they are properly seated and aligned. Apply a thin coat of clean engine oil or approved lubricant to aid installation and improve sealing.

- Reassembly: Carefully reinstall any components removed to access the injector nozzle holders. Torque bolts and fittings to manufacturer specifications to avoid over-tightening or under-tightening.

- Testing: Start the engine and monitor for any signs of leaks or abnormal operation. Check for fuel odors and inspect the area around the injector nozzle holders for any signs of leakage.

Follow us on Facebook for more parts.