-10%

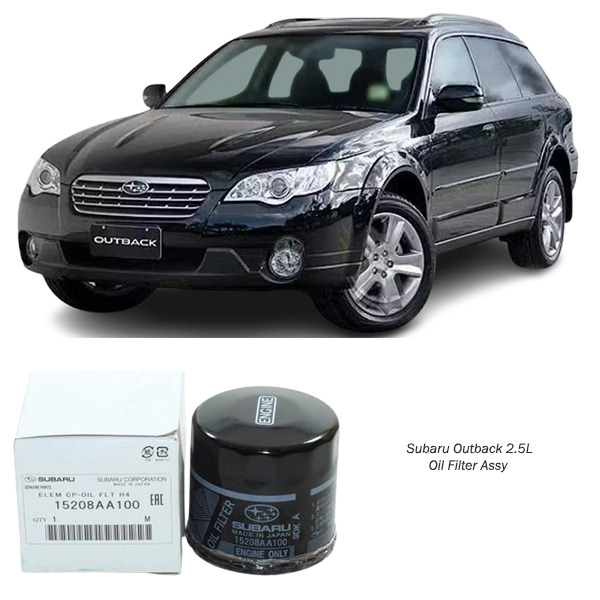

Get Subaru Outback 2.5L Oil Filter Assy 15208-AA100 in Kenya

An oil filter assembly is a critical part of an automobile’s lubrication system. It plays a vital role in maintaining engine health by ensuring that the oil circulating through the engine remains clean and free from harmful contaminants. This comprehensive guide explores the functions, benefits, types, maintenance, and considerations associated with oil filter assemblies.

What Is an Oil Filter Assembly?

The oil filter assembly consists of the oil filter itself, along with related components like the filter housing, mounting brackets, and sealing mechanisms. Its primary purpose is to trap contaminants such as dirt, metal particles, and carbon deposits from the engine oil, ensuring the oil is clean before it lubricates engine components.

How It Works

The oil filter assembly is integrated into the engine’s lubrication system. Here’s how it functions:

- Oil Flow: Engine oil is drawn from the oil sump and pumped through the oil filter assembly by the oil pump.

- Filtration Process: As the oil passes through the filter, contaminants are trapped by the filter medium, allowing clean oil to flow back into the engine.

- Bypass Mechanism: If the filter becomes clogged, a bypass valve allows unfiltered oil to circulate temporarily to prevent engine starvation.

- Continuous Cycle: This process repeats continuously as the engine operates.

Components of an Oil Filter Assembly

- Filter Housing: The outer shell or casing that encloses the filter element. It is typically made of metal or plastic and is designed to withstand high pressures.

- Filter Element: The core filtration material, often made from cellulose, synthetic fibers, or a blend of both. This is where contaminants are trapped.

- Anti-Drain Back Valve: Prevents oil from draining out of the filter when the engine is turned off, ensuring immediate lubrication upon startup.

- Bypass Valve: Allows oil to bypass the filter element if it becomes clogged, ensuring continuous lubrication.

- Sealing Mechanism: Includes rubber gaskets or O-rings to prevent oil leaks.

Types of Oil Filters

There are several types of oil filters, each designed for specific applications and engine requirements:

- Full-Flow Filters: Most common in modern vehicles, these filter all the oil before it circulates through the engine.

- Bypass Filters: Designed to filter a small portion of oil at a time, offering finer filtration.

- Cartridge Filters: Consist of a replaceable filter element without a metal housing.

- Spin-On Filters: The filter and housing are a single unit, making them easy to replace.

- Magnetic Filters: Use magnets to capture ferrous contaminants in the oil.

Benefits of an Oil Filter Assembly

- Improved Engine Performance: By keeping the oil clean, the filter ensures optimal lubrication, reducing friction and wear on engine components.

- Enhanced Longevity: Preventing contaminants from reaching critical engine parts extends the engine’s lifespan.

- Reduced Maintenance Costs: A properly functioning oil filter reduces the likelihood of engine damage, saving money on costly repairs.

- Environmental Protection: By trapping contaminants, the oil filter helps prevent pollutants from being released into the environment.

Maintenance of Oil Filter Assembly

Regular maintenance of the oil filter assembly is essential for engine health. Here’s a guide to keeping it in top condition:

- Follow Manufacturer’s Recommendations: Replace the oil filter according to the intervals specified in the vehicle’s owner’s manual, typically during every oil change.

- Inspect for Leaks: Check the filter assembly and surrounding areas for signs of oil leaks.

- Use Quality Filters: Always choose high-quality filters that meet or exceed OEM specifications.

- Monitor Oil Pressure: A clogged filter can cause a drop in oil pressure. Keep an eye on the oil pressure gauge or warning light.

- Flush the System if Necessary: If switching to a different oil type or after severe engine wear, consider flushing the system to remove debris.

Signs of a Failing Oil Filter Assembly

A malfunctioning oil filter can lead to serious engine issues. Be alert to these warning signs:

- Low Oil Pressure: A clogged filter can restrict oil flow, causing pressure to drop.

- Oil Leaks: Worn seals or gaskets in the filter assembly can lead to leaks.

- Engine Noise: Insufficient lubrication due to a faulty filter can cause increased friction, leading to abnormal engine noises.

- Dirty Exhaust: Excessive contaminants in the oil may burn off, causing smoke or a burning smell from the exhaust.

- Overheating: Lack of proper lubrication can result in excessive heat generation.

Selecting the Right Oil Filter Assembly

Choosing the correct oil filter assembly for your vehicle is crucial. Consider the following factors:

- Compatibility: Ensure the filter matches your engine’s make and model.

- Filtration Efficiency: Opt for filters with high dirt-holding capacity and fine filtration.

- Durability: Look for filters made from high-quality materials to withstand extreme conditions.

- Brand Reputation: Trusted brands like Bosch, Mann, or Wix often offer superior performance.

- Warranty: Many high-quality filters come with warranties that reflect their reliability.

The Role of Synthetic Oil in Oil Filter Efficiency

Synthetic oil is becoming increasingly popular due to its superior performance compared to conventional oil. However, it requires high-quality oil filters to maximize its benefits. Synthetic oil can last longer and handle higher temperatures, which means the oil filter must have a longer lifespan and higher dirt-holding capacity.

Environmental Considerations

Used oil filters contain residual oil and trapped contaminants, making them hazardous waste. Proper disposal is essential:

- Drain Used Filters: Remove excess oil from the filter before disposal.

- Recycle: Many service centers and recycling facilities accept used oil filters for recycling.

- Comply with Local Regulations: Follow local guidelines for disposing of automotive waste.

Advancements in Oil Filter Technology

Modern oil filters are designed with innovative features to meet the demands of advanced engines:

- High-Performance Media: Filters now use synthetic fibers or multi-layered materials for enhanced filtration.

- Eco-Friendly Designs: Some filters are designed to be more environmentally friendly, with biodegradable or recyclable materials.

- Integrated Sensors: Advanced filters may include sensors to monitor oil quality and filter condition in real-time.

Cost of Oil Filter Assemblies

The price of an oil filter assembly varies based on its type, quality, and brand. Spin-on filters for standard vehicles may cost as little as $10, while high-performance or specialized filters can exceed $50. For luxury or heavy-duty vehicles, prices may go higher.

Conclusion

The oil filter assembly is a small yet vital component of your vehicle’s engine. By ensuring clean oil circulation, it protects the engine from wear, improves efficiency, and extends its lifespan. Regular maintenance, timely replacement, and choosing the right filter are essential practices for maximizing the benefits of an oil filter assembly. Investing in quality filters not only safeguards your engine but also saves you from costly repairs and downtime, making it a key aspect of vehicle maintenance.

Follow us on Facebook for more parts.