-17%

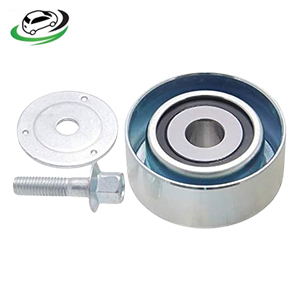

Get Tensioner Pulley Hilux Vigo Hiace Fortuner 0187-KDN145

A tensioner pulley is a crucial component in a vehicle’s engine that helps maintain the correct tension in the drive belt or serpentine belt. Here’s an in-depth look at the function, importance, and signs of issues with a tensioner pulley:

Function of a Tensioner Pulley:

- Belt Tension Adjustment:

- The primary function of a tensioner pulley is to maintain proper tension on the drive belt or serpentine belt in the engine.

- It ensures that the belt remains tight enough to transmit power from the crankshaft to various engine components such as the alternator, water pump, power steering pump, and air conditioning compressor.

- Automatic Tension Adjustment:

- Unlike manual belt tensioning systems, which require periodic adjustment, a tensioner pulley automatically adjusts the tension of the belt.

- This automatic adjustment compensates for belt stretch over time, changes in temperature, and other factors that can affect belt tension.

- Prevention of Slippage:

- Correct tension prevents the drive belt from slipping on the pulleys of engine accessories.

- Slippage can lead to reduced efficiency of engine-driven components, such as reduced charging by the alternator or inadequate cooling from the water pump.

- Reduced Wear and Tear:

- Properly tensioned belts experience less wear and tear, leading to longer belt and pulley lifespan.

- It helps in maintaining the overall reliability and performance of the engine’s accessory components.

Components of a Tensioner Pulley:

- Pulley: The tensioner pulley itself is a wheel with a grooved rim that allows the belt to run smoothly.

- Tensioner Arm: Connected to the pulley, the tensioner arm applies force to adjust the position of the pulley.

- Spring or Hydraulic Mechanism: Provides the force that applies tension to the belt, ensuring consistent tension as the engine operates.

Signs of Issues with a Tensioner Pulley:

-

- Squealing or Squeaking Noise:

- A common early sign of a failing tensioner pulley is a high-pitched squealing or squeaking noise coming from the engine bay.

- This noise typically occurs when the engine is running and may vary with engine speed.

- It indicates that the drive belt is slipping due to inadequate tension from the tensioner pulley.

- Grinding or Rattling Sounds:

- As the tensioner pulley wears further or if it becomes misaligned, you may hear grinding or rattling noises.

- These noises often indicate that the pulley is not rotating smoothly or that it may be hitting other engine components due to excessive play.

- Visible Wear or Damage:

- Inspect the tensioner pulley visually for signs of wear, such as cracks, chips, or grooves in the pulley itself.

- Also, check for damage to the tensioner arm or any mounting brackets associated with the pulley.

- Visible wear or damage suggests that the pulley is nearing the end of its service life and may need replacement.

- Belt Misalignment:

- A failing tensioner pulley can cause the drive belt to become misaligned with other pulleys in the engine.

- You may notice the belt not running smoothly on the pulleys or slipping off its intended path.

- Belt misalignment can lead to increased friction, accelerated wear on the belt, and potential damage to other engine components.

- Loose or Slack Belt:

- If the tensioner pulley fails to maintain proper tension on the drive belt, the belt may appear loose or have excessive slack.

- A loose belt can cause accessories like the alternator, water pump, or power steering pump to operate inefficiently or fail altogether.

- Failure to Maintain Belt Tension:

- In severe cases of tensioner pulley failure, the tensioner may no longer be able to maintain consistent tension on the drive belt.

- This can result in complete loss of power to engine accessories, leading to a breakdown or loss of vehicle functionality.

- Check Engine or Battery Warning Light:

- If the drive belt controls components like the alternator or water pump, failure of the tensioner pulley can trigger warning lights on the dashboard.

- Watch for indicators like the check engine light, battery warning light, or temperature warning light, which may signal issues with engine accessories.

- Squealing or Squeaking Noise:

Replacement and Maintenance:

- Replacement Interval: The tensioner pulley is typically replaced as part of scheduled maintenance or when signs of wear or failure are detected.

- Professional Inspection: If you suspect issues with the tensioner pulley, have a qualified mechanic inspect the entire belt drive system to diagnose and address any underlying problems.

- Belt Replacement: Often, it is advisable to replace the drive belt along with the tensioner pulley to ensure optimal performance and reliability.

Follow us on Facebook For more parts.