-9%

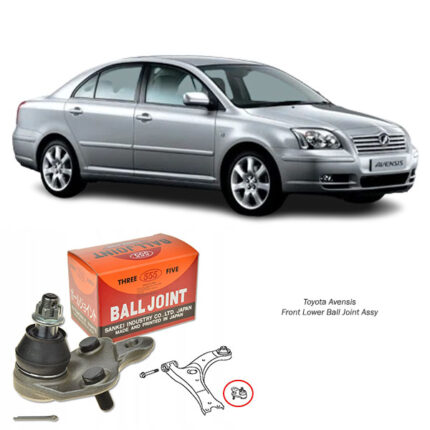

Get Toyota Avensis Front Stabilizer Link Assy SLT490 in Kenya

The front stabilizer link assembly is an integral component of a vehicle’s suspension system, playing a key role in maintaining stability and handling. This small but crucial part connects the stabilizer bar (or sway bar) to the suspension system, ensuring the vehicle remains stable during turns and uneven road conditions. This detailed overview explores its function, benefits, signs of wear, maintenance tips, and more.

What is a Front Stabilizer Link Assembly?

The front stabilizer link assembly is a rod-like structure with ball joints or bushings at both ends. It connects the stabilizer bar to the suspension components, usually the control arms or struts. Together, these components work to reduce body roll and enhance cornering performance, making driving safer and more comfortable.

Functions of the Front Stabilizer Link Assembly

- Minimizes Body Roll

- During cornering or sharp turns, the stabilizer link helps the stabilizer bar transfer forces between the left and right suspension systems.

- This reduces body roll and keeps the vehicle more balanced.

- Improves Handling Stability

- By connecting the stabilizer bar to the suspension, the link ensures that both sides of the vehicle’s suspension work in harmony.

- This improves traction and control, especially during sudden maneuvers.

- Enhances Ride Comfort

- The stabilizer link assembly absorbs and dampens road shocks, providing a smoother ride.

- Distributes Load Evenly

- It helps balance the vehicle’s weight distribution across all tires, reducing stress on individual suspension components.

Benefits of a Front Stabilizer Link Assembly

- Increased Safety

- A functional stabilizer link ensures better handling, reducing the risk of rollover during high-speed turns or sudden lane changes.

- Better Vehicle Dynamics

- The link enhances the overall driving experience by maintaining stability and minimizing unwanted body movements.

- Longevity of Suspension Components

- By distributing forces evenly, the stabilizer link reduces wear and tear on suspension parts like control arms and struts.

- Enhanced Tire Performance

- Balanced suspension prevents uneven tire wear, extending tire life and improving fuel efficiency.

Signs of a Faulty Front Stabilizer Link Assembly

Like any mechanical component, the stabilizer link assembly is subject to wear and tear. Here are common signs of a failing stabilizer link:

- Clunking or Knocking Noises

- Worn or damaged stabilizer links can create noise, especially when driving over bumps or uneven surfaces.

- Poor Handling

- A loose or broken stabilizer link reduces the vehicle’s ability to corner effectively, leading to excessive body roll.

- Uneven Tire Wear

- If the suspension system isn’t balanced, it can cause one side of the vehicle to carry more weight, leading to uneven tire wear.

- Excessive Body Roll

- A faulty stabilizer link may cause the vehicle to sway or lean excessively during turns.

- Visible Wear and Tear

- During an inspection, cracked bushings, rust, or play in the joints are indicators of a damaged stabilizer link.

Causes of Stabilizer Link Failure

- Regular Wear and Tear

- Over time, the constant stress of absorbing shocks and stabilizing the suspension causes the link’s components to degrade.

- Harsh Driving Conditions

- Driving on rough or uneven roads accelerates wear on the stabilizer link assembly.

- Corrosion

- Exposure to moisture, dirt, and road salt can corrode the metal parts, weakening the assembly.

- Overloading

- Carrying excessive weight in the vehicle puts extra stress on the suspension system, including the stabilizer link.

Maintenance Tips for Front Stabilizer Link Assemblies

- Regular Inspections

- Check the stabilizer link for visible damage or wear during routine vehicle maintenance.

- Listen for Unusual Noises

- Pay attention to clunking or knocking sounds when driving over bumps, as these may indicate a failing stabilizer link.

- Replace in Pairs

- If one stabilizer link fails, it’s advisable to replace both sides to ensure balanced suspension performance.

- Keep Suspension Components Clean

- Regularly wash your vehicle to remove dirt, salt, and debris that can cause corrosion.

- Avoid Overloading the Vehicle

- Stick to the manufacturer’s weight limits to prevent unnecessary stress on suspension components.

- Use Quality Replacement Parts

- Always opt for OEM or high-quality aftermarket stabilizer links to ensure durability and performance.

How to Replace a Front Stabilizer Link Assembly

Replacing a front stabilizer link assembly is a straightforward process for those familiar with automotive repairs. Here’s an overview of the steps:

- Preparation

- Gather tools such as a jack, jack stands, wrenches, and a socket set.

- Park the vehicle on a flat surface and engage the parking brake.

- Lift the Vehicle

- Use a jack to raise the vehicle and secure it on jack stands for safety.

- Remove the Old Stabilizer Link

- Locate the stabilizer link and remove the nuts or bolts attaching it to the stabilizer bar and suspension.

- Install the New Stabilizer Link

- Position the new link and secure it with the provided hardware. Ensure proper torque specifications as recommended by the manufacturer.

- Test the Suspension

- After installation, test-drive the vehicle to ensure the new stabilizer link resolves any handling or noise issues.

Common Issues with Stabilizer Link Assemblies

- Premature Wear

- Poor-quality materials or harsh driving conditions can cause the link to wear out faster than expected.

- Incorrect Installation

- Improper torque or misaligned components can lead to reduced performance and faster deterioration.

- Compatibility Issues

- Using a stabilizer link that isn’t designed for your vehicle can affect suspension dynamics.

- Neglected Maintenance

- Failing to replace worn links can strain other suspension components, leading to more extensive damage.

Advancements in Stabilizer Link Technology

Modern stabilizer links are designed with advanced materials and engineering to enhance durability and performance:

- Enhanced Ball Joint Designs

- Advanced ball joints offer smoother operation and longer lifespan.

- Corrosion-Resistant Coatings

- Special coatings protect the metal parts from rust and corrosion.

- Improved Bushing Materials

- High-quality rubber or polyurethane bushings provide better vibration damping and wear resistance.

- Lightweight Construction

- Some stabilizer links use lightweight materials like aluminum to reduce overall vehicle weight and improve efficiency.

Conclusion

The front stabilizer link assembly is a vital component for vehicle safety, handling, and comfort. By connecting the stabilizer bar to the suspension system, it minimizes body roll, enhances cornering stability, and ensures a smooth ride. Regular inspections, prompt replacement of worn parts, and adherence to maintenance best practices are essential for keeping the stabilizer link assembly in top condition.

Investing in high-quality components and addressing issues early can prolong the life of your suspension system and improve your overall driving experience. Whether you’re a DIY enthusiast or rely on professional mechanics, understanding the importance of this component will help you maintain a safer and more reliable vehicle.

Follow us on Facebook for more parts.