-7%

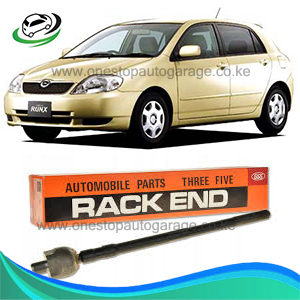

Get Toyota Corolla Nze Runx / Allex Steering Tie Rod End SE3641 in Kenya

The steering tie rod end is a critical component of a vehicle’s steering system, responsible for connecting the steering rack to the steering knuckle. Its function ensures smooth and accurate steering by transmitting force from the steering mechanism to the wheels. This guide explores its structure, function, types, maintenance, signs of failure, and replacement procedures, providing you with an in-depth understanding of this essential automotive part.

What is a Steering Tie Rod End?

A steering tie rod end is a small yet indispensable part of the steering system. It is essentially a ball-and-socket joint that allows for controlled movement of the wheels in response to steering input. Tie rod ends are located at the ends of the tie rods, connecting the steering linkage to the steering knuckle.

There are typically two tie rod ends per wheel:

- Inner Tie Rod End – Connected to the steering rack or center link.

- Outer Tie Rod End – Attached to the steering knuckle.

Together, they allow the front wheels to pivot smoothly, ensuring precise control over the direction of the vehicle.

Function of a Steering Tie Rod End

The primary role of the tie rod end is to:

- Transmit Steering Force:

- It transfers the rotational force from the steering gear to the wheels, enabling directional control.

- Facilitate Suspension Movement:

- The ball-and-socket design accommodates vertical and horizontal movement, allowing the suspension to absorb bumps without affecting steering performance.

- Maintain Wheel Alignment:

- By connecting the steering system to the wheels, tie rod ends help maintain proper toe alignment, ensuring stability and even tire wear.

Types of Steering Tie Rod Ends

Tie rod ends come in various designs to suit different vehicles and driving conditions:

- Standard Tie Rod Ends:

- Most common in passenger vehicles.

- Feature a ball joint with a threaded stud for secure connection.

- Adjustable Tie Rod Ends:

- Allow for adjustments to wheel alignment, specifically toe angle.

- Common in performance or modified vehicles.

- Sealed Tie Rod Ends:

- Pre-lubricated and sealed, requiring little to no maintenance.

- Durable but not serviceable if damaged.

- Serviceable Tie Rod Ends:

- Feature a grease fitting for regular lubrication.

- Ideal for vehicles exposed to harsh driving conditions.

Materials Used in Tie Rod Ends

- Steel:

- Offers high strength and durability.

- Common material for most tie rod ends.

- Aluminum:

- Lightweight alternative, used in performance-oriented vehicles.

- Prone to wear under extreme conditions.

- Composite Materials:

- Combine metals and polymers for reduced weight and enhanced corrosion resistance.

Advantages of a Steering Tie Rod End

- Precise Steering Control:

- Ensures accurate wheel response to steering inputs.

- Enhanced Stability:

- Maintains alignment and prevents vehicle drift.

- Improved Tire Longevity:

- Helps prevent uneven tire wear by ensuring proper alignment.

- Durability:

- High-quality tie rod ends withstand daily wear and tear, as well as extreme driving conditions.

- Adaptability:

- Suitable for various vehicle types, from compact cars to heavy-duty trucks.

Symptoms of a Failing Steering Tie Rod End

Like any mechanical component, tie rod ends wear out over time. Common signs of failure include:

- Unusual Noises:

- Clunking or knocking sounds, especially when turning or driving over bumps.

- Steering Play:

- Excessive looseness in the steering wheel, making the vehicle harder to control.

- Uneven Tire Wear:

- One side of the tire wearing more than the other indicates alignment issues.

- Vehicle Pulling:

- The car drifts to one side even on a straight road, signaling a problem with the tie rod end.

- Vibration:

- Steering wheel vibration, particularly at higher speeds.

- Visible Damage:

- Inspecting the tie rod end may reveal cracks, wear, or torn dust boots.

Maintaining Steering Tie Rod Ends

Proper maintenance can significantly extend the life of your tie rod ends:

- Regular Inspections:

- Check tie rod ends during routine vehicle servicing or after driving on rough terrain.

- Lubrication:

- Serviceable tie rod ends should be greased periodically to reduce wear.

- Wheel Alignment:

- Realign wheels after replacing tie rod ends or when signs of misalignment appear.

- Avoid Overloading:

- Excessive weight can strain the steering and suspension components.

- Protect Against Corrosion:

- Wash the undercarriage regularly, especially after driving in salty or wet conditions.

Replacing a Steering Tie Rod End

When tie rod ends show signs of wear or failure, they should be replaced promptly. Below is a general guide to replacing a tie rod end:

- Preparation:

- Gather tools such as a jack, wrenches, and a tie rod end puller.

- Ensure the vehicle is on a flat, stable surface.

- Remove the Wheel:

- Loosen lug nuts, lift the car with a jack, and remove the wheel to access the tie rod end.

- Mark the Current Position:

- Use chalk or a marker to note the alignment of the tie rod end for easy reassembly.

- Detach the Tie Rod End:

- Loosen the lock nut and remove the cotter pin securing the tie rod end.

- Use the tie rod puller to separate the joint from the steering knuckle.

- Install the New Tie Rod End:

- Thread the new tie rod end onto the tie rod, aligning it with the marked position.

- Secure it with the lock nut and cotter pin.

- Reassemble and Test:

- Reattach the wheel, lower the vehicle, and test the steering for proper operation.

- Perform a wheel alignment.

Troubleshooting Common Issues

- Premature Wear:

- Check for improper lubrication or damage to the dust boot.

- Alignment Issues:

- Ensure proper installation and always perform a wheel alignment after replacement.

- Persistent Noises:

- Inspect surrounding components such as ball joints and control arms.

FAQs About Steering Tie Rod Ends

- How long do tie rod ends last?

- Typically, they last 50,000 to 100,000 miles but can vary based on driving conditions.

- Can I drive with a failing tie rod end?

- It’s unsafe, as it compromises steering control and can lead to further damage.

- Should I replace both tie rod ends at the same time?

- It’s advisable, especially if both ends have similar wear levels.

- What causes tie rod ends to fail?

- Common causes include lack of lubrication, impact damage, and exposure to harsh environments.

Conclusion

The steering tie rod end is a small but essential component that ensures the safe and precise operation of your vehicle’s steering system. Regular inspections, timely maintenance, and prompt replacements are crucial for keeping your tie rod ends in optimal condition. Understanding their function and recognizing signs of wear can help prevent accidents, extend the life of your tires, and ensure a smooth driving experience.

Follow us on Facebook for more parts.