-7%

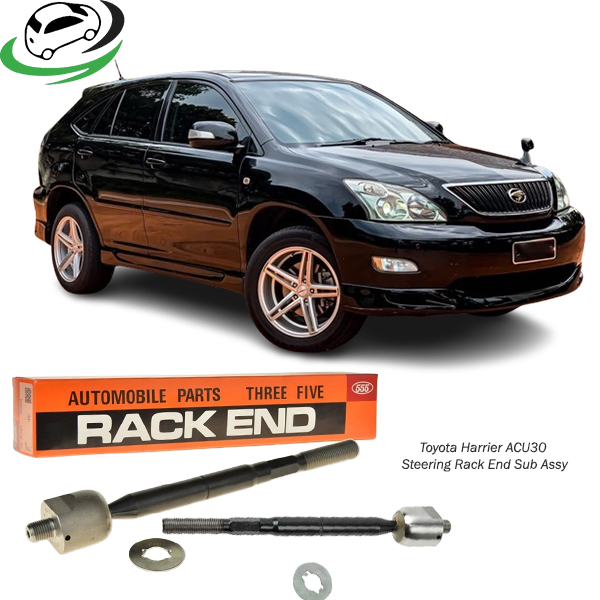

Get Toyota Harrier ACU30 / Lexus RX300 Steering Rack End Sub-Assy SR3901 in Kenya

The steering rack end sub-assembly is a key component in the steering system of most modern vehicles. It connects the steering rack to the steering mechanism and plays a crucial role in translating the driver’s steering input into movement of the wheels. This system ensures that a vehicle responds accurately to steering commands, providing the driver with control and maintaining the stability of the vehicle. In this article, we will explore the structure, function, types, maintenance, and signs of wear associated with the steering rack end sub-assembly.

1. Function and Importance of the Steering Rack End Sub-Assembly

The steering rack end sub-assembly is responsible for the final link in the steering system that connects the steering rack to the steering knuckle, which ultimately controls the direction of the wheels. When the driver turns the steering wheel, this motion is transmitted to the steering rack, which in turn moves the steering rack ends. The rack ends are critical in converting the linear movement of the rack into the rotational movement of the wheels. Essentially, they are the last stage in transferring the driver’s input to the wheels.

This component ensures that the wheels move in harmony with the steering wheel, providing responsive and stable handling. Without a properly functioning steering rack end sub-assembly, the steering system may become loose, imprecise, or unresponsive, creating safety hazards, especially in high-speed driving or sharp turns.

2. Components of the Steering Rack End Sub-Assembly

The steering rack end sub-assembly typically consists of several key components, each serving a specific function in maintaining the integrity of the steering system. These components include:

- Rack End: The primary component of the sub-assembly, the rack end is typically made of durable steel or cast iron. It connects directly to the steering rack and contains the mechanism that allows for the rotation of the steering knuckle. The rack end is designed to accommodate the movement of the steering system while maintaining a solid connection to the rest of the components.

- Ball Joint: Similar to a tie rod end, the rack end often includes a ball joint at its outermost point. This joint allows the rack end to pivot and rotate, permitting the wheels to adjust to changes in suspension geometry. The ball joint is housed in a protective boot, which helps keep contaminants out and ensures long-term reliability.

- Dust Boot: The dust boot is a rubber or synthetic cover that surrounds the ball joint, protecting it from dirt, water, and road debris. A damaged or cracked dust boot can lead to the rapid wear of the ball joint, as contaminants can enter and degrade the lubrication, ultimately shortening the lifespan of the steering rack end.

- Lock Nut/Pin: In some designs, the rack end is held in place by a lock nut or cotter pin to ensure that it remains securely fastened during operation. These securing mechanisms are crucial to maintaining the integrity of the connection and preventing the rack end from becoming loose.

- Threaded Shaft: The threaded shaft of the rack end connects to the steering rack. This shaft may be adjustable in some systems, allowing the mechanic to fine-tune the steering system’s alignment (e.g., toe angle). The adjustability of the rack end helps in aligning the front wheels correctly, ensuring optimal handling and tire wear.

3. Types of Steering Rack End Sub-Assemblies

There are several types of steering rack end sub-assemblies, with variations depending on the vehicle’s steering design and intended application. The main types include:

- Inner Rack Ends: These are connected to the steering rack and are generally located nearer to the center of the vehicle. The inner rack ends are responsible for receiving the motion from the steering rack and transferring it to the outer steering components, such as the tie rods.

- Outer Rack Ends: These are located closer to the wheels, connected to the steering knuckle. The outer rack ends play a critical role in steering the wheels in response to the driver’s input. They allow for the final pivot that turns the wheels.

- Adjustable vs. Non-Adjustable Rack Ends: Some steering rack ends are adjustable, meaning they can be lengthened or shortened to fine-tune the alignment of the wheels, particularly for toe angles. Non-adjustable rack ends are often found in vehicles with simpler steering designs and are typically replaced as an entire assembly.

- Power-Assisted Rack Ends: In vehicles with power steering systems, the rack end sub-assembly is often designed to work in conjunction with the hydraulic or electric power steering assist. These systems make it easier for the driver to turn the steering wheel by reducing the amount of force needed.

4. Symptoms of Wear or Failure in Steering Rack End Sub-Assemblies

The steering rack end sub-assembly is designed to be highly durable, but like all vehicle components, it is subject to wear over time. A failing or worn steering rack end can lead to a variety of symptoms that may negatively impact vehicle performance and safety. Common signs of wear include:

- Loose or Unresponsive Steering: A loose or worn rack end can cause the steering to feel slack or unresponsive. If the vehicle requires more effort to steer or if there is excessive play in the steering wheel, the steering rack end may be the cause.

- Clunking or Popping Noises: If the rack end ball joint becomes worn or loose, it may create a clunking or popping noise when the steering wheel is turned. This noise often occurs when the vehicle is turning or when driving over bumps.

- Uneven or Rapid Tire Wear: A misaligned steering system due to a failing rack end can lead to uneven tire wear. This is often most noticeable on the inner or outer edges of the tires, as the wheels are no longer properly aligned with the vehicle’s centerline.

- Steering Pulling: A worn or damaged rack end can cause the steering to pull to one side, which means the wheels are not moving evenly in response to steering input. This can make driving difficult and increase the risk of accidents, particularly when driving at high speeds.

- Vibrations in the Steering Wheel: If there is excessive play or looseness in the rack end, the steering wheel may vibrate, especially when driving at highway speeds. These vibrations can be felt through the wheel and are typically accompanied by other symptoms of wear.

5. Maintenance and Replacement of Steering Rack End Sub-Assemblies

Proper maintenance of the steering rack end sub-assembly is essential to keep the steering system functioning correctly and to avoid premature wear or failure. Here are some important maintenance and replacement tips:

- Regular Inspection: Inspect the steering rack end regularly, particularly if you experience any symptoms of wear. Look for damage to the dust boot, signs of rust or corrosion on the rack end, and check for excessive play or movement in the ball joint.

- Lubrication: Some rack ends feature grease fittings that allow for periodic lubrication. Lubricating the rack ends can help reduce friction and wear on the ball joint, extending the life of the component.

- Alignment Checks: If the steering rack end has been replaced, or if there are any signs of steering misalignment, it is crucial to check the vehicle’s alignment. Misaligned wheels can lead to uneven tire wear, reduced handling, and poor fuel efficiency.

- Replace in Pairs: When replacing steering rack ends, it is often recommended to replace both sides (left and right) at the same time. This ensures that the vehicle’s steering remains balanced and consistent, improving overall performance.

- Use OEM Parts: When replacing steering rack ends, it’s essential to use high-quality, OEM (Original Equipment Manufacturer) parts. OEM parts are designed specifically for the vehicle’s specifications, ensuring that they fit and function properly.

6. The Replacement Process

Replacing a steering rack end involves the following steps, which are generally performed by a professional mechanic:

- Lift the Vehicle: Use a jack to lift the vehicle and secure it with jack stands. Remove the wheels to gain access to the steering rack and tie rod ends.

- Remove the Tie Rod: Loosen and remove the tie rod end from the steering knuckle. This step requires the use of a special puller tool to avoid damaging the surrounding components.

- Remove the Steering Rack End: Once the tie rod end is disconnected, remove the old steering rack end from the steering rack.

- Install the New Rack End: Thread the new steering rack end onto the steering rack, ensuring that it is tightly secured.

- Reassemble the Tie Rod: Attach the tie rod end to the steering knuckle and tighten the locking nut or cotter pin.

- Align the Wheels: After installation, perform a wheel alignment to ensure proper handling, tire wear, and steering response.

Conclusion

The steering rack end sub-assembly is a critical component that ensures the accurate and responsive steering of a vehicle. It plays a crucial role in connecting the steering rack to the steering knuckle, allowing the driver to maintain control over the direction of the vehicle. Regular inspection, timely maintenance, and proper replacement are essential to ensure the longevity and proper functioning of the steering rack end sub-assembly. By recognizing the signs of wear and understanding how this component functions, vehicle owners can maintain safe and reliable steering performance.

Follow us on Facebook for more parts.