-9%

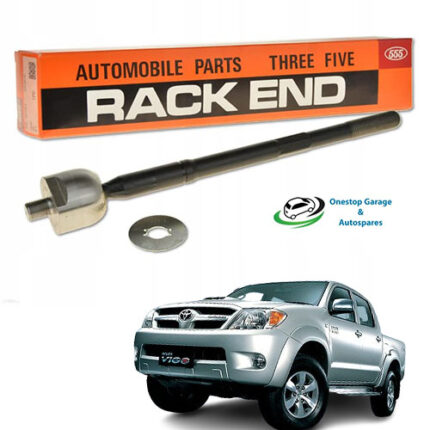

Get Toyota Hilux Vigo 4WD Tie Rod End Sub-Assy SE3981 in Kenya

The tie rod end sub-assembly is a crucial component in a vehicle’s steering system, connecting the steering rack to the steering knuckle on each front wheel. This connection allows for precise control over the direction of the wheels, translating the driver’s input from the steering wheel to the wheels on the road. In this guide, we’ll explore the function, construction, types, symptoms of wear, and maintenance of the tie rod end sub-assembly, along with its importance to steering performance and safety.

1. The Function of the Tie Rod End Sub-Assembly

The tie rod end sub-assembly plays a key role in the steering mechanism by transferring motion from the steering rack (or gearbox) to the wheels. As the driver turns the steering wheel, the steering rack moves the tie rods, which then push or pull on the tie rod ends. This movement causes the wheels to turn in the desired direction, allowing the vehicle to steer left or right.

In addition to enabling steering, the tie rod end sub-assembly also helps maintain alignment and stability in the front wheels, preventing unwanted movement or vibration. Tie rod ends play a vital role in maintaining proper toe alignment (the angle of the wheels in relation to each other) and ensuring that the wheels respond predictably to steering input.

2. Components of the Tie Rod End Sub-Assembly

The tie rod end sub-assembly comprises several key components that work together to create a durable, flexible, and precise connection between the steering system and the wheels:

- Tie Rod Shaft: The tie rod itself is a rod-shaped component that connects the tie rod end to the steering rack. It is usually constructed from durable metal, such as steel, and may be adjustable to allow for alignment adjustments.

- Ball Joint: The ball joint is located at the end of the tie rod, connecting it to the steering knuckle. This ball-and-socket structure allows the tie rod to pivot in multiple directions, accommodating the various movements of the suspension while maintaining a solid connection to the wheels.

- Dust Boot: A rubber or synthetic boot surrounds the ball joint, protecting it from dirt, moisture, and contaminants. This boot prevents premature wear by keeping the ball joint lubricated and free from debris.

- Nut and Locking Mechanism: The tie rod end is usually secured to the steering knuckle with a nut, which is often paired with a cotter pin or lock nut to prevent loosening due to vibrations. Proper fastening is essential to ensure safe operation.

3. Types of Tie Rod End Sub-Assemblies

There are a few different types of tie rod ends, each suited for specific vehicle configurations and steering system designs:

- Inner Tie Rod Ends: The inner tie rod ends are located closer to the steering rack or gearbox, connecting the steering rack to the outer tie rods. They are usually longer and sometimes feature an inner ball joint to allow for smooth motion in the steering system.

- Outer Tie Rod Ends: The outer tie rod ends are located near the wheel assembly, connecting the inner tie rods to the steering knuckle. They feature an outer ball joint to pivot as the wheel moves up and down with the suspension, enabling steering while accommodating suspension travel.

- Adjustable vs. Fixed Tie Rod Ends: Adjustable tie rod ends allow for fine-tuning of wheel alignment, particularly toe angle, which is essential for accurate steering and tire wear. Fixed tie rod ends, on the other hand, are not adjustable and are generally used in simpler steering systems or for non-adjustable configurations.

4. Importance of the Tie Rod End Sub-Assembly

The tie rod end sub-assembly’s role in a vehicle is critical, as it directly affects steering performance, safety, and handling. Here’s why it’s essential:

- Steering Accuracy: By providing a precise connection between the steering wheel and wheels, tie rod ends ensure that the vehicle responds accurately to the driver’s input. Loose or worn tie rod ends can result in delayed steering response or a loose steering feel.

- Vehicle Stability and Alignment: Tie rod ends help maintain the alignment of the wheels. Proper alignment is crucial for vehicle stability, as misaligned wheels can lead to uneven tire wear, poor handling, and increased fuel consumption.

- Suspension Flexibility: With a built-in ball joint, tie rod ends can pivot, accommodating the movement of the wheels as they encounter bumps or dips in the road. This flexibility is key to maintaining control and comfort while driving.

- Safety: Given that the tie rod end sub-assembly connects directly to the steering knuckle, any failure in this component can have serious safety implications, potentially leading to a loss of steering control.

5. Signs of Wear or Failure in Tie Rod End Sub-Assemblies

Over time, tie rod ends can wear out or become damaged due to exposure to road conditions, vibrations, and stress from steering and suspension movement. Common symptoms of a worn or failing tie rod end include:

- Clunking or Knocking Noise: A loose or worn ball joint in the tie rod end can create a clunking or knocking sound, especially when turning or driving over bumps. This noise indicates excessive play in the joint, often due to wear or a torn dust boot.

- Loose or Wobbly Steering: If the tie rod ends are worn out, you may notice that the steering feels loose or unresponsive. This can make it difficult to maintain control of the vehicle, particularly at higher speeds.

- Uneven or Rapid Tire Wear: Worn tie rod ends can affect wheel alignment, leading to uneven or rapid tire wear. This wear pattern is often most noticeable on the inside or outside edge of the tires, as the wheels are no longer aligned correctly.

- Poor Alignment: When tie rod ends become loose or worn, they can throw off the vehicle’s alignment, causing it to pull to one side or the other. This misalignment can lead to poor handling and increased tire wear.

- Excessive Play in the Steering Wheel: If the tie rod ends are loose, the steering wheel may have a noticeable amount of play before the wheels respond. This can be a dangerous condition, especially when quick steering response is needed.

6. Maintenance and Replacement of Tie Rod End Sub-Assemblies

Routine maintenance and timely replacement of tie rod ends are essential for safe and effective steering. Here are some steps to help maintain tie rod ends:

- Regular Inspections: Inspect tie rod ends regularly, especially if you experience any of the symptoms mentioned above. Look for signs of a damaged dust boot, which can allow dirt and moisture to enter the ball joint, accelerating wear.

- Lubrication: Some tie rod ends are designed with grease fittings, allowing for regular lubrication. This helps keep the ball joint smooth and prevents wear. If your vehicle’s tie rod ends have grease fittings, ensure they are lubricated according to the manufacturer’s recommendations.

- Check Alignment After Replacement: Whenever a tie rod end is replaced, it’s important to check and adjust the alignment to prevent uneven tire wear and ensure proper handling. Most alignment shops will adjust toe angle as part of this process.

- Replace in Pairs: Even if only one tie rod end is worn, it’s often recommended to replace both tie rod ends (left and right) at the same time. This ensures balanced performance and reduces the likelihood of uneven wear.

- Use High-Quality Parts: High-quality tie rod ends are made from durable materials and designed to withstand tough road conditions. Choosing reliable parts can help extend the life of the steering components and reduce the need for frequent replacements.

7. Replacement Process for Tie Rod End Sub-Assemblies

Replacing a tie rod end typically involves the following steps, which should be performed by a professional or someone with mechanical experience:

- Jack Up the Vehicle: Lift the vehicle securely and remove the wheel to access the tie rod end.

- Loosen the Lock Nut: A lock nut is often used to secure the tie rod end to the tie rod. Loosen this nut without fully removing it to avoid altering alignment settings.

- Disconnect the Tie Rod End: Use a puller tool or hammer to separate the tie rod end from the steering knuckle. Care must be taken not to damage the surrounding components.

- Install the New Tie Rod End: After removing the old tie rod end, screw on the new one, ensuring it’s tightened to the proper specifications.

- Tighten the Lock Nut and Secure with Cotter Pin: Once the new tie rod end is in place, secure it with the lock nut and insert a new cotter pin if applicable.

- Recheck Alignment: Once the installation is complete, it’s essential to check and adjust the alignment as needed.

Conclusion

The tie rod end sub-assembly is a vital component that ensures accurate steering, stable handling, and safe operation. Proper maintenance, timely replacement, and using high-quality parts are crucial to keeping the tie rod ends functioning well. Recognizing signs of wear, such as clunking noises, loose steering, and uneven tire wear, can help prevent serious steering issues and maintain a smooth, controlled driving experience. By understanding its construction, function, and maintenance requirements, drivers can appreciate the essential role tie rod ends play in both everyday driving and overall vehicle safety.

Follow us on Facebook for more parts.