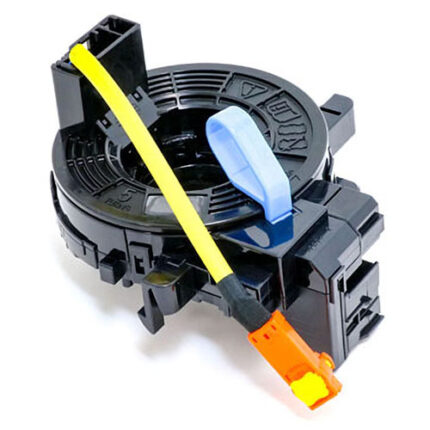

Get Toyota Landcruiser Prado 150 Series Spiral Cable Sub-Assembly with Sensor 84307-47020 in Kenya

In modern vehicles, safety and efficiency in steering control have become critical aspects of automotive engineering. The Spiral Cable Sub-Assembly with Sensor, also known as a clock spring with sensor, plays an essential role in ensuring proper electrical connections between the vehicle’s steering wheel and other crucial systems, such as airbags, horn, and steering wheel controls. This component is particularly important for vehicles with advanced driver assistance systems (ADAS) and electronic steering aids.

This detailed guide will explore the functionality, components, benefits, failure symptoms, and maintenance tips of a spiral cable sub-assembly with a sensor.

1. What is a Spiral Cable Sub-Assembly with Sensor?

A spiral cable sub-assembly is an electromechanical component located inside the steering column. It serves as a flexible electrical conductor that maintains a continuous connection between the steering wheel and the car’s electrical systems, even when the wheel is turned in either direction.

The sensor integrated into the sub-assembly can be a steering angle sensor, which helps the vehicle’s stability control system detect the position and rotation of the steering wheel. This sensor is critical for systems like Electronic Stability Control (ESC), Traction Control (TCS), and Advanced Driver Assistance Systems (ADAS).

2. Components of a Spiral Cable Sub-Assembly with Sensor

A typical spiral cable sub-assembly consists of the following key components:

a) Flexible Flat Ribbon Cable

- A ribbon-like conductive strip that coils and uncoils as the steering wheel turns, maintaining electrical connectivity.

b) Plastic Housing

- The housing encases the spiral cable, protecting it from dust, debris, and mechanical damage.

c) Steering Angle Sensor

- The integrated sensor detects the precise position and rotation speed of the steering wheel, providing crucial data for stability and steering assistance systems.

d) Connectors & Terminals

- Connectors link the spiral cable to various electrical systems, such as the airbag module, horn, cruise control, and audio controls on the steering wheel.

e) Return Spring Mechanism

- Ensures that the spiral cable maintains tension and does not overextend when the steering wheel is turned.

3. Functions of the Spiral Cable Sub-Assembly with Sensor

a) Maintains Electrical Connectivity

The primary function of the spiral cable sub-assembly is to keep electrical signals flowing between the steering wheel and vehicle electronics while allowing the wheel to rotate freely.

b) Airbag Deployment System

The spiral cable ensures a continuous connection between the airbag control unit and the driver’s airbag. A damaged cable can cause the airbag system to malfunction, leading to a potential safety hazard.

c) Steering Angle Detection for Stability Control

The steering angle sensor (SAS) within the assembly detects the position and rotation of the steering wheel. This data is critical for systems like:

- Electronic Stability Control (ESC) – Helps prevent skidding.

- Traction Control System (TCS) – Improves vehicle grip.

- Lane Keep Assist (LKA) – Aids in maintaining the vehicle in its lane.

d) Enables Steering Wheel Controls

The sub-assembly provides connectivity for buttons and controls on the steering wheel, such as:

- Audio controls

- Cruise control settings

- Bluetooth and hands-free call buttons

e) Assists in Power Steering Functionality

Some advanced electric power steering (EPS) systems rely on the spiral cable sub-assembly sensor for precise steering inputs.

4. Benefits of a Spiral Cable Sub-Assembly with Sensor

a) Enhances Safety

Ensures that airbags deploy correctly, preventing potential failure due to electrical disconnection.

b) Supports Advanced Driver Assistance Systems (ADAS)

Works with stability control, traction control, and lane-keeping assist to improve driving safety.

c) Improves Steering Accuracy

The steering angle sensor provides real-time data, ensuring the vehicle’s stability and handling remain optimal.

d) Enables Seamless Vehicle Control

Drivers can easily control various functions on the steering wheel, reducing distractions while driving.

e) Long-Lasting & Durable

Made from high-quality plastic and copper conductors, the spiral cable is designed to last for several years under normal driving conditions.

5. Signs of a Failing Spiral Cable Sub-Assembly

A faulty spiral cable can cause multiple issues, as it is responsible for various electrical connections within the vehicle. Below are common symptoms of failure:

a) Airbag Warning Light on the Dashboard

- A broken spiral cable can disconnect the driver’s airbag circuit, triggering an airbag system malfunction warning.

b) Non-Responsive Steering Wheel Controls

- If the horn, audio buttons, or cruise control stop working, a faulty spiral cable might be the cause.

c) ESP or Traction Control Warning Light

- If the steering angle sensor within the assembly fails, electronic stability control (ESC) and traction control (TCS) systems may be disabled.

d) Clicking or Grinding Noise when Turning the Steering Wheel

- A worn-out spiral cable can produce clicking or grinding sounds inside the steering column.

e) Steering Response Issues

- Faulty steering angle sensor signals can cause unstable handling or steering assist malfunctions.

6. Maintenance & Replacement Tips

a) Regular Inspection

- Have the spiral cable assembly checked during routine vehicle maintenance.

- Ensure the steering wheel controls and airbag system are functioning properly.

b) Avoid Over-Rotating the Steering Wheel

- Excessively turning the steering wheel beyond its limit may damage or break the ribbon cable inside the assembly.

c) Use Diagnostic Tools for Troubleshooting

- If you notice warning lights related to the airbag or stability control, use an OBD-II scanner to check for fault codes related to the steering angle sensor or airbag system.

d) Professional Replacement Recommended

- If the spiral cable is faulty, it is best to have it replaced by a qualified technician to ensure correct airbag and steering system functionality.

e) Reset the Steering Angle Sensor after Replacement

- After replacing the spiral cable, the steering angle sensor must be recalibrated using a diagnostic tool to prevent misalignment issues.

7. Conclusion

The Spiral Cable Sub-Assembly with Sensor is a critical component in modern vehicles, ensuring proper electrical connectivity, airbag functionality, and steering stability. With an integrated steering angle sensor, it plays a crucial role in advanced safety systems like Electronic Stability Control (ESC) and Traction Control (TCS).

Regular inspection and timely replacement of a failing spiral cable can prevent serious electrical malfunctions and safety risks. Whether for daily driving or high-performance vehicles, a well-functioning spiral cable assembly ensures enhanced steering control, improved safety, and a better driving experience.

Follow us on Facebook for more parts.