-10%

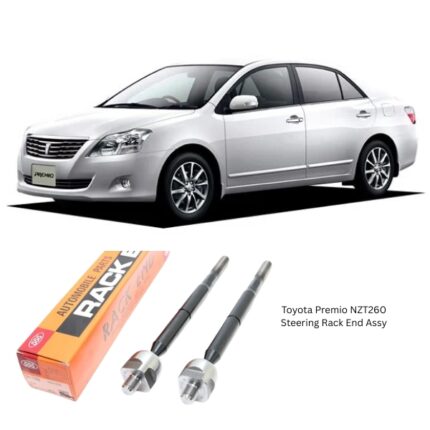

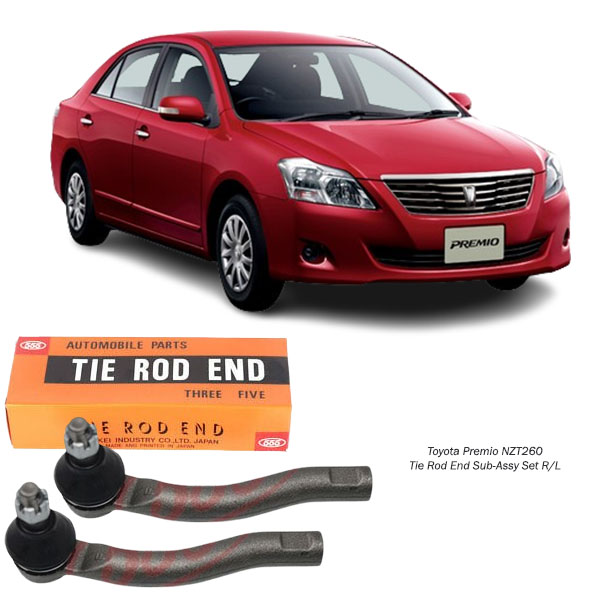

Get Toyota Premio NZT260 Tie Rod End Sub-Assy Set R/L SE-3931 R in Kenya

The tie rod end sub-assembly set (R/L) is a critical component in a vehicle’s steering system, connecting the steering rack to the front wheels. It ensures smooth steering operation, allowing the driver to control the direction of the car with precision.

This component plays a crucial role in stability, handling, and safety. A worn or damaged tie rod end can lead to steering issues, uneven tire wear, and potential accidents. In this guide, we’ll discuss the function, components, working mechanism, signs of failure, replacement process, and maintenance tips for the tie rod end sub-assembly set.

1️⃣ What is a Tie Rod End Sub-Assembly Set?

The tie rod end sub-assembly set consists of two tie rod ends – one for the right side (R) and one for the left side (L) of the vehicle. These components are essential for transmitting steering force from the steering rack to the front wheels, allowing the vehicle to turn smoothly.

✔️ Connects the steering system to the wheels

✔️ Helps maintain wheel alignment

✔️ Absorbs road shocks and vibrations

✔️ Ensures smooth and responsive steering

Each tie rod end is equipped with a ball joint, which allows movement in multiple directions, adapting to the suspension and road conditions.

2️⃣ Components of a Tie Rod End Sub-Assembly

A tie rod end assembly consists of several parts that work together to provide smooth steering performance.

Main Components:

🔹 Outer Tie Rod End – The part that connects to the steering knuckle.

🔹 Inner Tie Rod End – Connects to the steering rack and links to the outer tie rod.

🔹 Ball Joint – Allows pivoting motion for smooth wheel movement.

🔹 Castle Nut & Cotter Pin – Secures the tie rod end to the steering knuckle.

🔹 Rubber Boot / Dust Cover – Protects the ball joint from dirt and moisture.

🔹 Threaded Adjustment Area – Used for setting wheel alignment during installation.

These components work together to provide accurate steering control and reduce wear on the steering mechanism.

3️⃣ How Does a Tie Rod End Work?

The tie rod end assembly functions as the bridge between the steering system and the front wheels. Here’s how it works:

1️⃣ Steering Input – When the driver turns the steering wheel, the steering rack moves left or right.

2️⃣ Tie Rod Movement – The inner tie rod transfers this motion to the outer tie rod end.

3️⃣ Wheel Rotation – The outer tie rod end is connected to the steering knuckle, causing the wheels to turn in the desired direction.

4️⃣ Ball Joint Action – The ball joint inside the tie rod end allows for movement in multiple directions, accommodating bumps, suspension movement, and road variations.

This system ensures smooth and responsive steering, while also allowing the wheels to move independently over uneven surfaces.

4️⃣ Signs of a Worn or Failing Tie Rod End 🚨

A damaged tie rod end can cause serious steering problems. Here are the most common symptoms of a failing tie rod end:

❌ Loose or Unstable Steering – Steering feels vague or requires constant correction.

❌ Uneven or Rapid Tire Wear – A worn tie rod end disrupts wheel alignment, causing excessive tire wear.

❌ Steering Wheel Vibration – Loose tie rod ends can cause shaking or vibrations in the steering wheel, especially at higher speeds.

❌ Knocking or Clunking Sounds – A bad tie rod end may produce clunking noises when turning or driving over bumps.

❌ Car Pulling to One Side – Uneven steering response may cause the car to drift left or right.

❌ Difficulty Turning – Steering may feel stiff or unresponsive.

Ignoring these warning signs can lead to serious steering issues and even complete loss of control while driving.

5️⃣ Causes of Tie Rod End Failure

Several factors contribute to the wear and tear of tie rod ends:

🔹 Normal Wear & Tear – Constant movement and stress cause gradual deterioration.

🔹 Road Conditions – Potholes, rough roads, and off-road driving accelerate wear.

🔹 Lack of Lubrication – A damaged rubber boot allows dirt and moisture to enter, leading to corrosion and failure.

🔹 Accidents or Hard Impacts – Hitting curbs or potholes can bend or break tie rod ends.

🔹 Misalignment – Poor alignment puts extra stress on the tie rods, leading to premature wear.

Regular inspection and timely replacement prevent costly repairs and unsafe driving conditions.

6️⃣ How to Replace a Tie Rod End Sub-Assembly Set (R/L)? 🛠️

Replacing tie rod ends is an essential maintenance task to ensure safe steering control. Here’s how to do it:

Tools Required 🛠️

✔️ Jack & Jack Stands

✔️ Lug Wrench

✔️ Wrench Set

✔️ Pliers

✔️ Torque Wrench

✔️ Tie Rod End Puller / Ball Joint Separator

✔️ Grease & Thread Locking Compound

Step-by-Step Replacement Guide:

1️⃣ Lift the Vehicle – Secure the car on jack stands and remove the front wheels.

2️⃣ Locate the Tie Rod Ends – Identify the inner and outer tie rod ends connected to the steering knuckle.

3️⃣ Remove the Cotter Pin & Castle Nut – Use pliers to remove the cotter pin, then unscrew the castle nut.

4️⃣ Separate the Tie Rod End – Use a ball joint separator to detach the tie rod end from the steering knuckle.

5️⃣ Unscrew the Outer Tie Rod – Loosen the locknut and unscrew the outer tie rod end from the inner tie rod.

6️⃣ Install the New Tie Rod End – Screw in the new tie rod end, ensuring it’s properly aligned.

7️⃣ Reattach the Castle Nut & Cotter Pin – Secure the tie rod end to the steering knuckle.

8️⃣ Tighten & Torque to Specification – Use a torque wrench to ensure proper tightening.

9️⃣ Reinstall Wheels & Lower the Vehicle – Put everything back together and double-check alignment.

🔟 Perform Wheel Alignment – Always get a professional wheel alignment after replacing tie rod ends.

Proper installation ensures smooth steering, stability, and even tire wear.

7️⃣ Maintenance Tips for Tie Rod Ends 🔧

To extend the lifespan of your tie rod end sub-assembly, follow these maintenance tips:

✔️ Regular Inspections – Check for loose, worn, or damaged tie rod ends every 10,000 – 15,000 miles.

✔️ Keep Ball Joints Lubricated – Grease the ball joints if they are serviceable.

✔️ Check for Alignment Issues – If your car pulls to one side, get an alignment check.

✔️ Avoid Rough Terrain – Driving on bad roads accelerates wear.

✔️ Replace in Pairs – Always replace both left and right tie rod ends for balanced steering.

Proper care ensures better handling, longer tire life, and safer driving.

Conclusion 🎯

The tie rod end sub-assembly set (R/L) is a small but vital component of the steering system. Worn or damaged tie rods can cause serious handling problems, tire wear, and safety risks.

📌 Key Takeaways:

✔️ Ensures accurate steering and stability

✔️ Worn tie rod ends cause steering problems & tire wear

✔️ Replace both right & left tie rod ends together

✔️ Get a wheel alignment after installation

Regular inspection and maintenance help keep your vehicle safe, smooth, and responsive!

Follow us on Facebook for more parts.